What are Specialised Clamps?

When it comes to specialised clamps, we look at clamps that are industry specific and offer specialised functions for specific applications in different industries. Bessey has a wide range of different clamps from universal clamps that offer wider functionality and some that offer users a more specific use. These clamps form part of the very unique clamps tradespeople invest in, from welders to carpenters and mechanics specialised clamps play an important role in ensuring these trades are able to get the job done.

As we look at specialised clamps we highlight the different industries and applications these clamps are mostly used in. Bessey has been designing and manufacturing world-class clamping tools for decades with one mission – to ensure tradespeople have access to quality clamping tools that are ‘Simply better’. In terms of different applications BESSEY specialised clamps have provided the many different trades with specific solutions that have made the job much easier and more effective.

We have included 4 different BESSEY specialised clamps and we will be focusing on these 4 unique specialised clamps. We have featured BESSEY’s most used specialised clamps: Angle clamps, C-frame edge clamp, Lever clamps and G clamps or C clamps. These clamps are used in different applications and provide the best flexibility for users as they are heavy-duty specialised clamps.

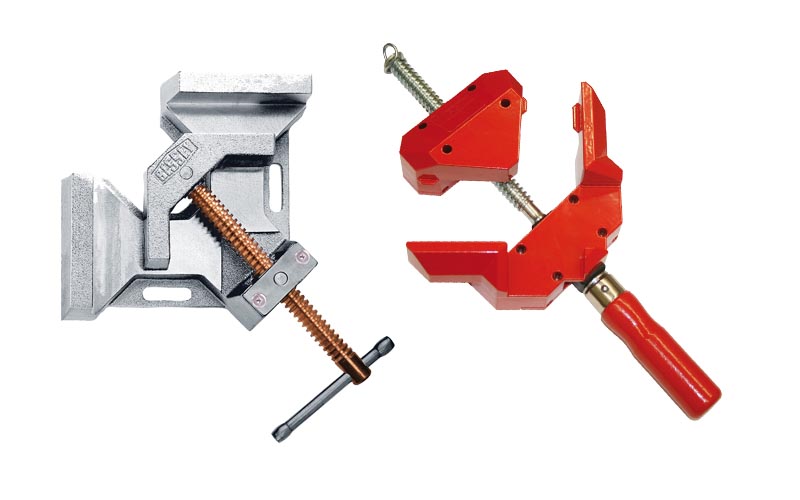

Angle Clamps

Angle Clamps are designed for clamping objects at a specific angle. As the tool is often used for clamping corners or creating mitre joints, it can also be referred to as a corner clamp or mitre clamp. The device allows two items to be held at a 90-degree angle, in order to be attached together. These clamps give users the versatility of creating unique pieces.

What to consider when selecting the correct angle clamp?

Joining various materials like wood or metal, or any other material at a right angle can be a somewhat daunting task. A right-angle clamp can make the entire project easier, but only if you select the correct one. To determine which right-angle clamp is best for your workshop, it’s important to consider factors like durability, accuracy, price point and clamping range.

BESSEY Angle Clamp WS-3+2K Applications:

- Cabinet work

- Furniture assembly

- Framing

Welders Angle Clamp Applications:

- Steel construction

- Welding

- Metalworking

- Holding materials

- Fixing and aligning materials

Angle Clamp benefits:

The construction of the right-angle clamp is key to its performance. The cheaper light-duty clamps are made from thinner aluminum or even plastic, these will work well for light-duty jobs, such as framing or hobby projects, but won’t hold up to clamping together heavier materials for projects like cabinet building or metal welding. For heavy-duty tasks, look for clamps with reinforced aluminum bodies and steel spindles and arbores.

It automatically adjusts to workpieces of various thicknesses; it has sturdy jaws and a thick base plate made from high-quality cast iron. The copper-plated spindle prevents the welding spatter from sticking to the spindle. It also provides precise 90-degree angles.

Accuracy and material type go hand in hand. The heavier-duty clamps won’t warp or bend under pressure, which allows for a perfect 90-degree angle. Clamps with a single handle make accuracy much easier as it clamps both pieces simultaneously.

If you are in the market for any heavy-duty specialized clamps, make sure the clamp is suitable for the materials being clamped. The greater the jaw’s width, the more stable the clamp and it can hold longer and heavier materials in place.

Bessey C-Frame Edge Clamp

Three-spindle C-frame clamp, extra strong, with a forged frame, universally applicable within the fields of wood and metal processing and is ideally suited to welding applications.

Everyone knows how difficult it is to do edging on a workpiece, especially on unusual shapes. The Bessey KT8-3 is exactly what you need. It’s that extra set of hands that makes edging so much easier and simpler. It has three spindles, applying pressure from the top and bottom, and a centre spindle that applies pressure that holds the edging in place that is either glued or welded.

Bessey C-frame Edge Clamp Applications:

- Apply any sort of edging material(wood, sheeting) and hold it on edges.

- Hold material around corners, curves, and edges.

Clamp Benefits:

- Clamping force up to 18000 N

- Drop forged, stable

- Copper plated spindle prevents the adhesion of the welding spatter

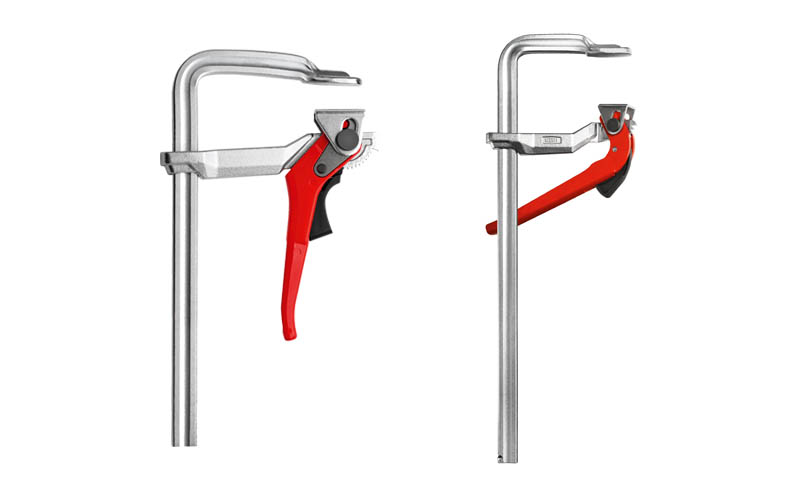

Bessey Lever Clamp

The clamping lever made of glass-fiber reinforced plastic is ergonomically shaped and has a multi-step locking mechanism to enable quick and easy clamping and releasing of the clamp. Compared to normal screw clamps, the desired clamping pressure is thus achieved faster.

Clamp Benefits:

They offer an enhanced clamping force and are quicker to set up and release. In fact, it is five times faster than your average screw-type clamp setup. The lever clamps get set up once in place by the pull of the handle and released by the pull of a trigger.

Due to the clamp jaw being pulled tight by a gear, this makes lever clamps vibration resistant and the various sizes have a huge clamping force. They are used for both wood and metal.

Bessey Lever Clamp Applications:

- Clamping wood

- Holding work wood or metal sheeting

- Woodworking

- Metal working

They have a large tilting pressure plate that makes it easier to secure the material. The rail profile offers a higher clamping force and the trigger protection prevents you from having pinched fingers, a power ratchet mechanism, and a new U-shaped sliding arm offer you a straight-line power transmission.

G clamps or C clamps

A C-clamp or G-clamp is a type of clamp device typically used to hold a wood or metal workpiece and is often used in, but not limited to, carpentry and welding.

These clamps are normally very versatile and multi-purpose clamps. They are used for woodworking and metalworking. Extra care should be taken when working with softer woods as over-tightening can damage the materials. The flat gripping edges which are about an inch depending on the size of the clamps can cause an indentation on the material. This can be avoided by using scrap pieces of wood in between the material. This allows the scrap pieces of wood to be in direct contact with the final material and avoid any damage.

Clamp Benefits:

These Bessey clamps also feature clamps that come with a copper spindle that does not allow the welding spatter to stick to the spindle making it easier to open and close and easily just allowing users to brush off any spatter. They also have a clamping force of up to 18000N, are drop-forged, and are extremely stable. This makes maintenance a lot easier and simpler.

G/C Clamps Applications:

- Woodworking

- Welding

- Building

- Clamping and holding of wood or metal workpieces

For over 100 years BESSEY has been providing the highest quality clamping solutions to professional craftsmen and will continue to build on that legacy. As experts in the best clamping tools in the market, we are tasked with the duty to ensure you get the best out of your clamping tools and also understand how they can make your job easier and quicker.

We are here to help you and your workshop get the best possible result when it comes to your workshop output and productivity levels. Helping you understand why BESSEY is Simply Better.