A|C|T- Advanced Façade Installation System

A|C|T- Advanced Façade Installation System

fischer makes installing complex facades effortless and cost-effective

As advancements are made in manufacturing and fixing technologies, more creative building designs and architectural masterpieces are now possible. Gone are the days of being stuck with no choice but brick and mortar exterior walls with plaster and paint as the only finish available, elaborate, and complex façades are increasingly turning buildings into works of art. That is where fischer’s ACT (Advanced Curtain Wall Technique) System comes in. This innovative fixing system allows for the effortless and cost-effective design and installation of attractive and complex façades.

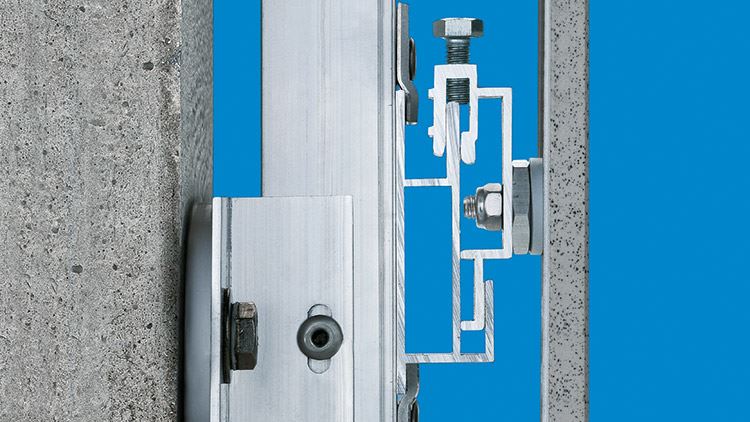

ACT is an innovative and high-quality system used for installing ventilated facades. This system allows architectures and planners to realise their creative vision for a building safely. The ACT system can accommodate up to 20mm thick ashlar boards, as well as up to 6mm thick ESG and TVG glass plates. Furthermore, the position of the fixing anchor on the back of the board is freely selectable. The exchange of single or all boards is easy to handle, and the system also allows reveal panels to be easily fixed with a high degree of flexibility.

The undercut technology, in connection with the fischer Zykon-Panel Anchor FZP-II ensures that there are no visible ixing elements at the joint ensuring a seamless finish.

The fischer ACT System allows for the effortless and cost-efficient design and installation of attractive, complex façades. The fischer Zykon panel anchor (FZP II) has an undercut design allowing for a stress-free fixing system that is installed into pre-drilled undercut holes.

This technology offers several times higher ultimate load bearing capacity than conventional fixings, ensuring a safe and secure façade installation. Because anchor positioning can be optimised, the risk of bending within the panel is reduced by up to 50% when compared to traditional systems. This allows for reduced panel thickness and larger panel sizes to be accommodated for. In addition, the varied panel thickness can be compensated using stand-off anchors.

ACT System technology perfectly combines the use of panel anchors, individual substructures, and sophisticated drilling technology. This combination makes installation fast and simple.

fischer’s framework substructure is an integral part of ACT system technology and is designed for:

- High loads

- Large-size and heavy natural stone panels

- For bridging non-bearing structural elements

SystemOne reduces on-site installation time and noise, for example during renovation works, and makes replacing panels easier.

SystemOne light is an efficient solution ideal for installing ventilated claddings made of lightweight façade panels. As you would expect, this rail-based system also offers all the advantages that make SystemOne unique:

- Fast installation thanks to hook and hang system

- No anchoring points visible within joint

- Designed for high loads

- Bridging of non-bearing structural elements

- Perfect for over-cladding of steel-frame constructions

- Mechanical fixing for reveal panels

- Non-destructive replacement of façade panels

Wall bracket system:

- Minimized cold bridges

- Reduced drilling costs

- Noise reduction during renovation works

- Dry installation, even at extreme temperatures

The ACT drilling technique makes use of state-of-the-art technology which is essential for drilling the undercut anchor holes for the installation of the ACT system consisting of a drilled hole and anchor.

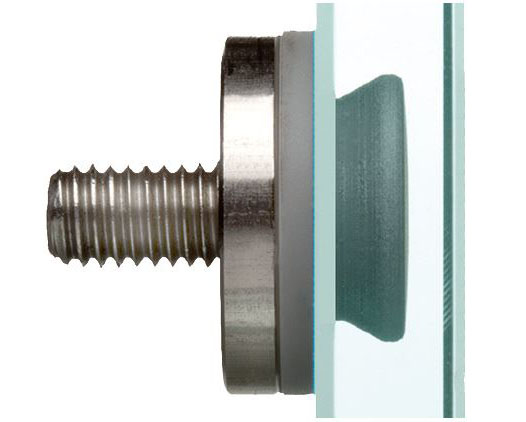

For drilling, fischer offers in-house developed machines in various sizes ranging from portable machines for onsite use through to large-scale, serial production facilities. These machines allow fast and cost-effective drilling of holes thanks to diamond-tipped drilling tools. Setting appliances are then used to fit the anchors into the panels.By using undercut technology, fischer has succeeded in creating the first point-fitting for glass in the world in which the hole does not penetrate the glass.

The FZP-G-Z involves an undercut point fitting made from stainless steel. It consists of a cone bolt, expansion sleeve, plastic cap, shim washer and retaining nut. The smooth outside of the glass façade offers the Architect a broader design field, while at the same time, the susceptibility to soiling and cleaning requirements are reduced.

The fischer FZP-G-Z is offered in two variations for glazing with toughened safety glass (ESG or ESG-H) and laminated safety glass (VSG). The glass panes can be enameled or coated and can also serve as substrates for solar elements that are laminated on.

Technical Support

Our Technical team has years of knowledge, and practical experience and are here to assist with all aspects related to your façade installation: