Basic Anchor Design Theory

An essential part of the building and construction industry is anchor design theory. It is also our area of expertise here at Upat SA due to being the official agents for fischer fixings. when helping SA’s Jobsites Build The Bigger Picture. The team here at Upat SA have been helping Jobsite across South Africa to ‘Build The Bigger Picture’ since 1983 and will continue to provide customers with high-quality construction and building brands.

When it comes to any element of fixing, be it general anchoring systems, handrail design, post-installed rebar connection, pipe installations, or facade elements Upat SA has you #fischerFixed with our range of Market Leading Anchoring Products. It’s also the reason we asked our Inhouse Engineer, Nikhiel Budhai to help outline the fundamentals of Basic Anchor Design Theory.

Table of Contents:

- What is anchoring and why is it important

- Anchoring into different substrates

- Drilling Actions

- Loads and Failure modes

- Anchor Spacing, edge distance, and member thickness

What is anchoring and why is it important

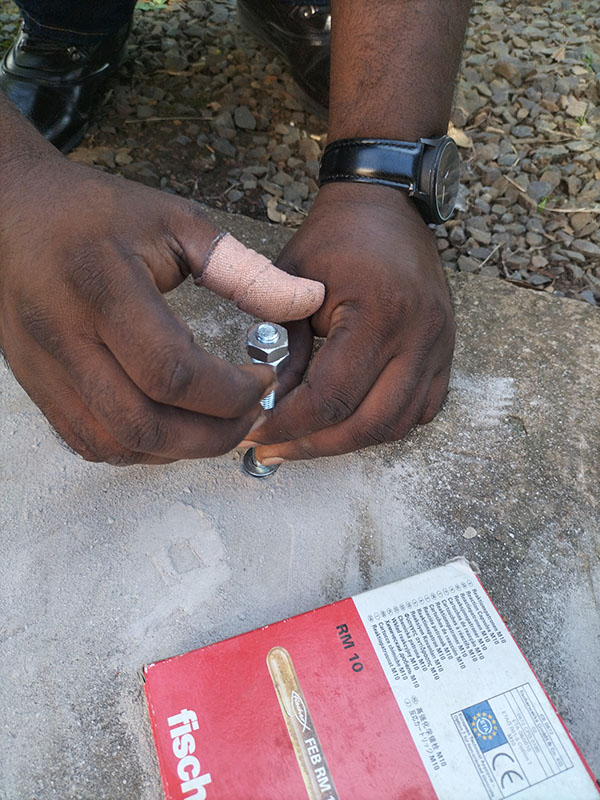

Anchoring can be understood to be the process by which structural and non-structural elements are fixed into substrates to transmit loads into a substructure. When creating an anchor there are two options to consider: Cast-in Anchors, which are anchor bolts that are cast in wet concrete, whereas post-installed anchors are installed in a pre-drilled hole in solid concrete. At Upat SA we know that fischer believe’s in Innovative Solutions, and that is why we only supply post-installed anchors, to save you money, rework, and time.

In engineering, all competent engineers are bound by a set of codes. The SANS 51992 – 4 2021 is South Africa’s first code for the Design of Fastenings for use in Concrete and sets a previously unknown standard of safety when it comes to the design and use of fastenings into concrete. As an integral part of the county’s anchoring safety architecture, Upat SA played an important part in the adoption of these codes in the construction industry.

The anchor design code Upat helped get adopted is the SANS 51992 Code for Anchor Design, which is based on the Eurocode, one of the world’s most stringent and safety-focused codes available. The code addresses the fundamentals of anchor design, load resistance, and limit state design, which includes ultimate and serviceable limits.

Let’s look at this code and anchor design in general.

Back to topAnchoring into different substrates

On any given Jobsite there are different types of substrates and building materials that will need to be fixed into, and each has its own set of characteristics. When working on South African job sites you will come across many different substrates, into which anchorings need to be made. Unfortunately, the reality is that the stronger the substrate, the better the anchor will perform, thus making the anchor connection much more reliable as opposed to weaker building substrates.

That’s why we here Upat SA have put together a small guide on the most common anchoring substrates and what to expect when anchoring into them.

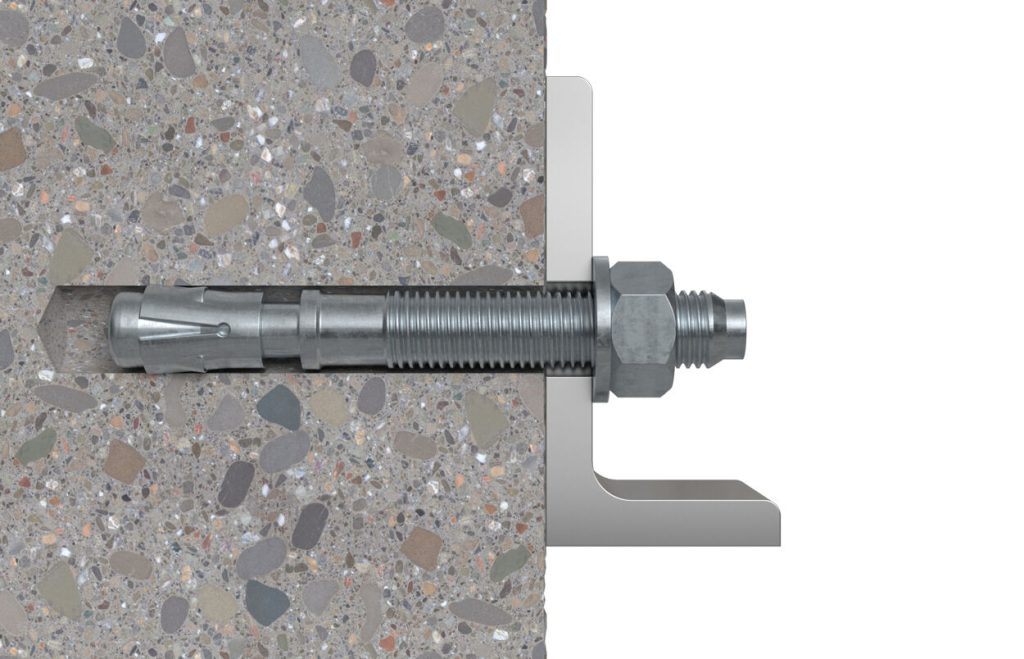

Concrete:

Concrete has a high level of compressive strength but low tensile strength, this indirectly affects the type of anchor used and the performance of the anchor. The load-bearing capacity of heavy-duty fixings is largely dependent on the compressive and tensile strength of the concrete base, which makes concrete the ideal anchor base substrate.

Masonry:

Masonry includes all substrates that are laid by a mason. The strength of masonry substrates is dependent on the type of brick used, either solid or perforated, and the material of brick, clay, aerated concrete, fly-ash, or cementitious brick, being used. Most often one will find that brickwork is being used in load-bearing walls or in conjunction with reinforced concrete to create a substructure.

Solid bricks with a dense structure are highly compressive resistant and most suitable for anchoring, as compared to other masonry types below.

Solid bricks with porous structures generally have large pores resulting in lower compressive strength. When anchoring with this substrate, it is best to use special anchors that are approved for use in this substrate. The fixings most suited to this building substrate will have longer expansion zones or be chemically bonded anchors.

Perforated brick with a dense structure has cavities in the brick and gives a weaker compressive strength as compared to solid bricks. This is why special anchors should be used in this application when considering your anchor design safety.

Perforated brick with a porous structure creates a porous nature in this type of brick. The compressive strength is the lowest and is not an ideal substrate for anchoring. However, in situations where the substrate cannot be changed, engineering principles are used to evaluate a safe-working anchor connection through longer expansion zones and chemically bonded anchors.

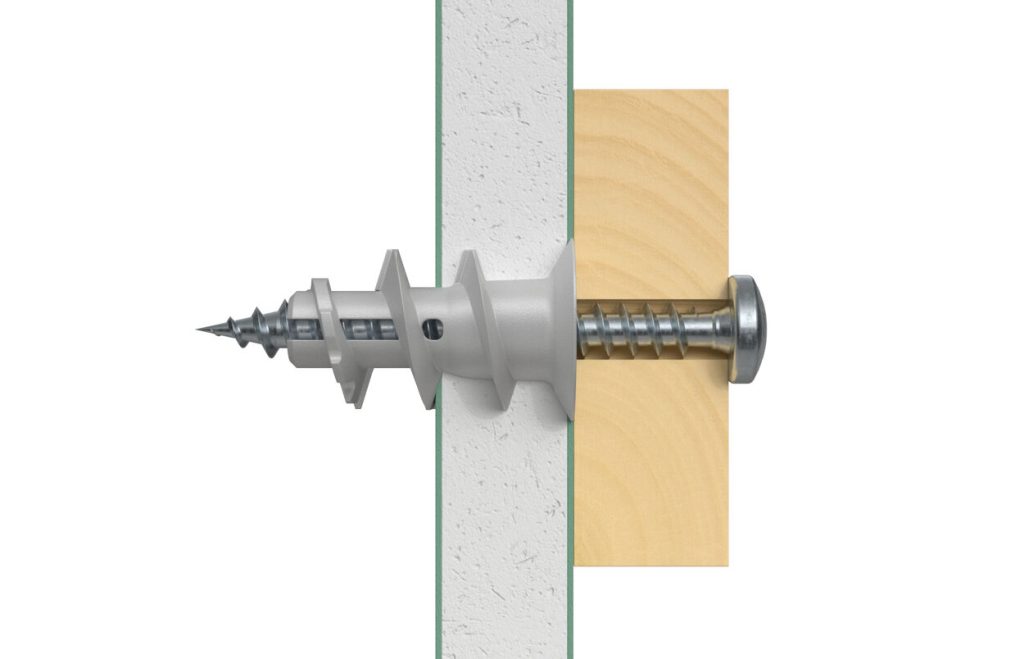

Drywall panels:

This substrate consists of thin-walled materials with limited strength, when compared to concrete and masonry substrates. Examples of this substrate include plasterboards, laminated wood, gypsum, or fiberboard. The overall application for this substrate is for non-load bearing walls and cladding in walls and roofs. When working with this substrate, light-duty fixings should be used to accommodate the weak nature of this substrate.

Back to topDrilling actions can be separated into five categories

Now that we have covered substrates it becomes relevant to know what drilling action is necessary to ensure the correct anchoring application for the given substrate. When installing anchors drilling action is required, with the substrate determining the drilling action that should be used when fixing an anchor.

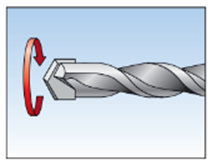

Impact Drilling

Uses a high number of light impact strokes with rotation. This drilling action is suitable for densely structured substrates such as concrete sections or solid brick.

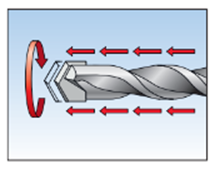

Rotary Hammer Drilling

Is a drilling action that uses a low number of heavy impact strokes with high impact energy with rotation. This is suitable for densely structured substrates such as concrete sections or combined hollow and solid brick.

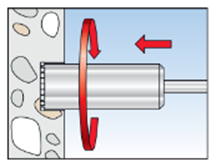

Diamond or Core Drilling

Is used for larger drill hole diameters in concrete or heavily reinforced connections and is the preferred drilling solution when noise or vibration must be reduced.

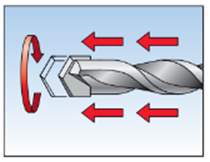

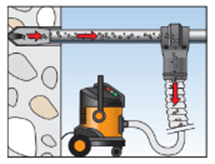

Hollow drilling

Is done through a special bit with a hollow core that is connected to a vacuum. This drilling method cleans the hole whilst drilling, meaning no further cleaning or brushing is required and is suitable for densely structured substrates such as concrete sections.

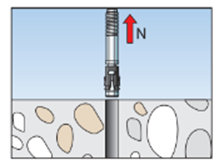

Never forget that while installing anchors, drill hole depth and hole cleaning processes play a major impact on the overall load-bearing capacity of the anchor. It is also important to keep in mind that when using mechanical anchors the overall drill hole depth should be longer than the anchorage depth. This is to ensure that the bolt has enough room at the end to reach maximum expansion of the anchor. On the other hand, when using chemical anchoring systems, it is important to ensure the drill hole is cleaned, through blowing and brushing, as this affects the overall load-bearing capacity.

Back to topLoads and failure modes

When choosing a suitable anchor, it is important to know the resulting load actions on the anchor connection. The resulting load actions are affected by the following parameters:

- Dimension: the quantity of load which is typically a force or weight action.

- Direction: tensile, compressive, shear, moment actions or a variation of these per load case.

- Type of load: refers to the intervals of load application this could be statically dormant, dynamic rising or changing, shock or seismic activity.

- Point of application: refers to the eccentricity of the load relative to the anchor connection.

The above parameters will determine the overall strength capacity and suitability of an anchor connection.

There are different types of loads associated with the anchor design theory. For example, ‘permissible loads’ are specified for products with approvals, whereas products without approvals have a ‘recommended load’. Both these load types have a safety factor included which can be used to evaluate whether the connection is safe. To predict a safe-working situation, it is important to understand what happens when anchor connections fail.

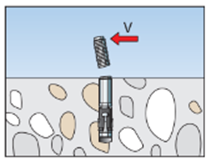

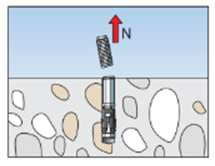

There are four failure modes associated with anchor failure:

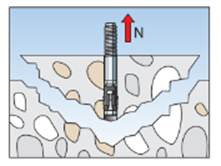

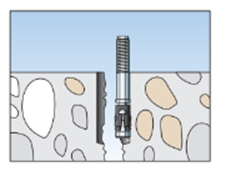

Steel failure – insufficient steel strength for the applied force

Pull-out failure – friction failure and/or adhesion failure due to high load or incorrect application.

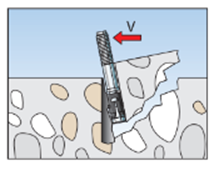

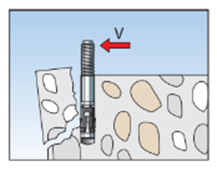

Anchor base failure – when the anchor base is much weaker than the applied force.

Anchor base splitting – occurs with insufficient component dimensions.

Anchor spacing, edge distance, and member thickness

To avoid spalling, cracking, and splitting of the base material, the minimum values for all spacing checks should be followed. These spacing checks include and are typically supplied in a product’s technical datasheet.

Anchor spacing – the distance between two adjacent anchors.

Edge distance – distance from the fixing to a free edge of the structural element.

Member thickness – thickness of the structural element.

If you are unsure about any anchor installation’s spacing, edge distance or member thickness then fischer has you covered with their free anchor design software based on Eurocode Design. Fixperience is freely available on the fischer International website, and is widely used to design and evaluate different applications of anchor design, namely:

- C-FIX – Design of steel and bonded anchors in concrete as well as injection systems in masonry

- RAIL-FIX – Design of railings on reinforced concrete and staircases

- REBAR-FIX – Design of post-installed rebar into reinforced concrete

- FACADE-FIX – Design of facade elements on buildings

- INSTALL-FIX – Design of service trays (i.e. overhead cable trays, service pipes)

- WOOD-FIX – Design of fixing into timber connections

- CHANNEL-FIX – Design of cast-in channels

FIXperience also comes with a mortar volume calculator that is essentially helpful when working with chemical anchor systems. This function allows you to determine the precise volume of chemicals required per fixing and the overall project.

Back to topFinal Thoughts

Basic Anchor Theory is an important part of any Jobsite that wants to be held to the highest safety standards. At Upat SA we are here to help all the Jobsites in SA Build The Bigger Picture by providing the support needed so that our construction sites can compete with the best in the world. If you have any questions or need more information on Basic Anchor Theory please get in touch with our Inhouse Engineer through support@upat.co.za. We can’t wait to help you get the best out of your anchoring solutions, by helping you use the best anchoring technology our industry can offer.