Toggle Clamps- Get More Out Of Your Tools

Toggle clamps are extremely popular amongst tradesmen in the woodworking, steel work and electronics trade. These clamps are highly recommended by many industry experts who have used them to perfect their projects. Let’s dive into toggle clamps and unpack how to get the most of your toggle clamps whether you work in cabinetry manufacturing, steel welding work or more general DIY applications.

What Are Toggle Clamps?

Toggle clamps are quick-action clamps that use an over-center locking mechanism known as a toggle action to secure workpieces in place for welding, drilling, grinding, and other machining operations.

The advantages of these clamps are that they can be easily adjusted to fit the specific requirements of the job at hand. They are available in a wide variety of sizes and styles to suit any application. They are easy to set up and use and provide reliable clamping force even under heavy loads. With their unique toggle action design, they provide significant clamping strength, while also having an quick release mechanism making your work faster and easier.

Toggle Clamp Uses

Toggle Clamp Functionality

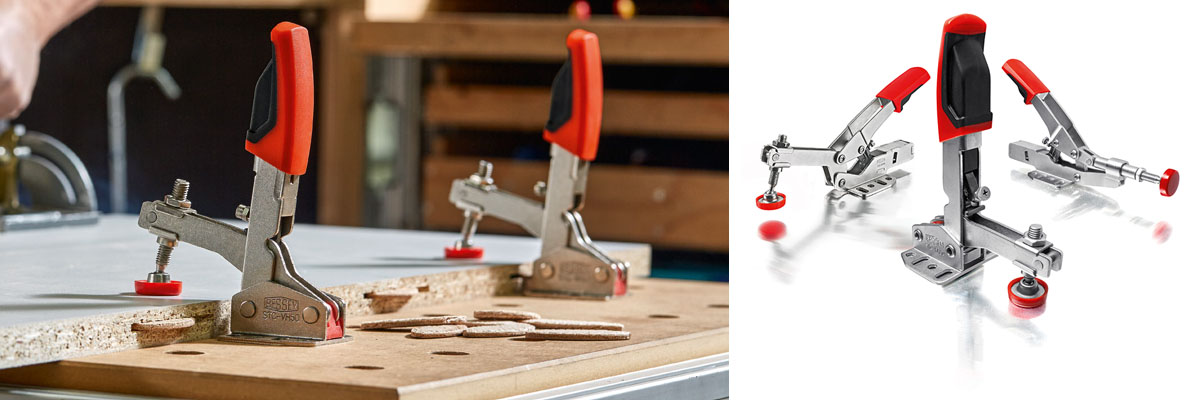

Toggle clamps are an essential tool for many different applications. They are typically used to hold parts and objects in place, providing a secure grip without the need for glueing or fastening. They are also used in electronics to hold components, wires, and other devices together during the manufacturing process. Additionally, toggle clamps can be used as machine tool positioners for the precision positioning of mechanical elements and parts.

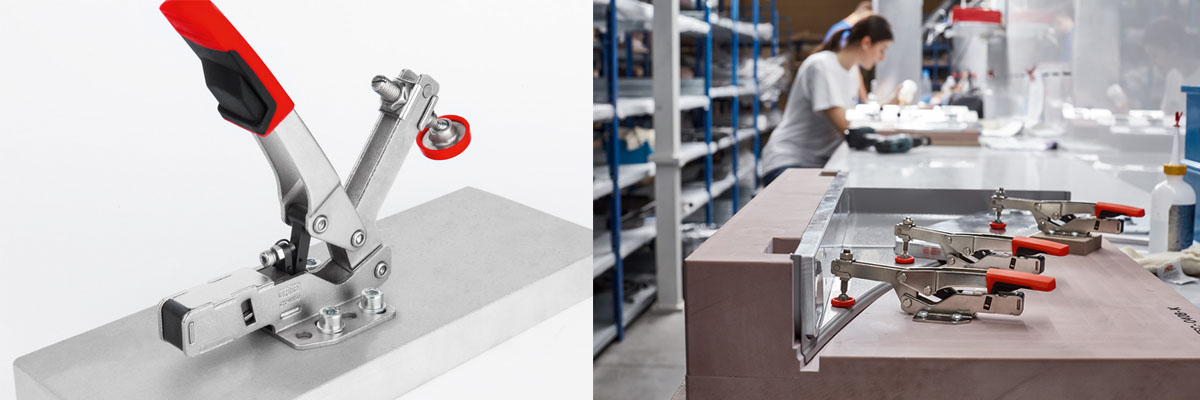

With their versatility and robust construction, toggle clamps have become indispensable tools in many industries ranging from precision machining to electronic assembly.

Toggle clamps are some of the most important tools for many industrial applications. They allow for efficient and reliable clamping of a workpiece, in order to guarantee that it remains immobile during the manufacturing process. These tools form part of an important tool functionality when working with any form of project that requires clamping and stability.

To increase the hand force at the handle into a high clamping force, they use a toggle mechanism. This mechanism consists of two levers, which when pulled together create an over-center locking action, allowing for an increased clamping pressure on the workpiece, ensuring it stays firmly in place during machining or other operations

Toggle Clamp Advantages

- Quick release action saves time

- Easy set-up with not additional machining

- Variety of toggle clamp sizes

- Require little maintenance aside from lubrication

- They are affordable

- High clamping force

Toggle Clamp Functionality

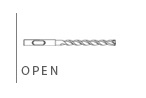

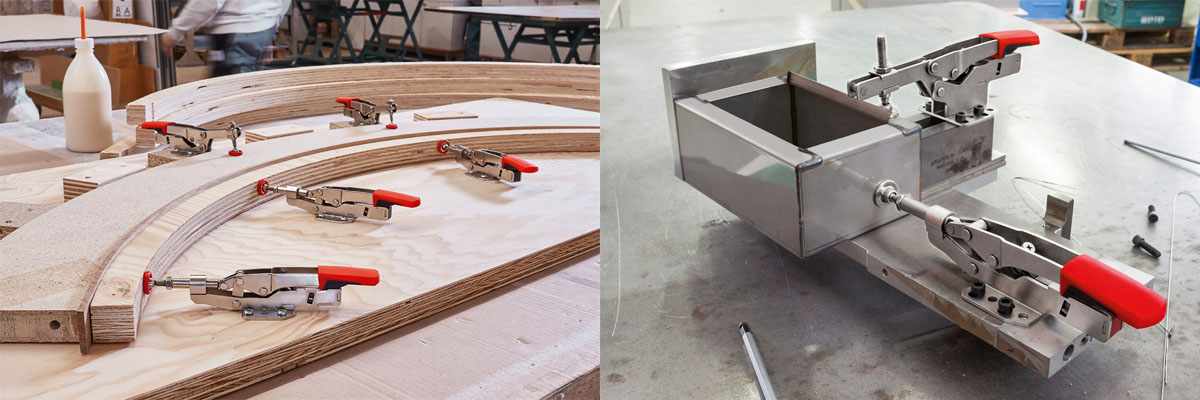

The variable Bessey STC Toggle Clamp combines innovative technology with the highest Bessey quality. Bessey toggle clamps have an extremely large clamping range and deliver a clamping force up to 250kg. The pattern on the base plate is designed to facilitate fast and secure clamping setups for metric and imperial.

Fitted with high-quality oil-resistant two-component plastic handles, allows even sensitive workpieces, e.g., with veneered or varnished surfaces, to be gently clamped.

Toggle clamps can be classified as either vertical or horizontal depending on the orientation of the handle. Vertical toggle clamps have a vertical handle, whereas horizontal toggle clamps have a horizontal handle. Both types will apply a clamping force when you engage the handle.

Clamping force

Clamping force is an important factor to consider when choosing a toggle clamp. This is because it determines the force that will be applied to the objects being connected together. The higher the clamping force, the more secure and rigidly held together two or more objects will be, however using a clamp with an extremely high clamping pressure on soft materials will cause indentations that will ruin your finished project.

Different toggle clamps are designed for different applications. When selecting your toggle clamp to take into consideration the pressure you’ll need and most importantly the materials being clamped i.e. softwood versus metal application will require different clamping pressures.