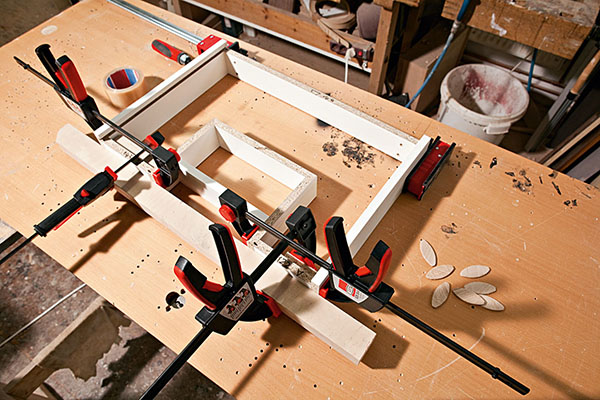

Never Underestimate The Quality Of Your Clamps

Wood and metal working clamps tend to be some of the most underrated tools in a workshop, but they serve a crucial role. Having low-quality clamps not only causes user frustrations but all your hours of hard work could be undone when your finished piece is not square because the steel of your clamp bent during the setting phase or wood bite leaves you with an ugly finish. Well-trained, professional craftsmen know just how important a set of quality clamps can be in saving time on woodworking and metalworking projects and BESSEY prides itself on providing ‘Simply Better’ clamps to their users since 1889. When it comes to quality clamps, no clamp can compete with the BESSEY range of clamps.

How Many Clamps Should You Have In Your Workshop?

When it comes to the number of clamps your workshop should have, the minimalist approach does not apply. The more clamps you have, the more hands you have, and the easier it is to get the job done. Most DIY’ers only have two clamps in their range, but if you’re a professional builder or fabricator you should own more clamps than you can count.

Every workshop application requires its own specific sort of clamp, a G Clamp is needed for welding and a Pipe Clamp is used for large woodworking projects. Clamps come in various sizes and designs to make your project easier and faster and the more hands you have, the more work you can get done.

Different Clamps For Different Applications

It’s good to remember that a clamp, no matter its application, has two jaws that adjust their size to clamp down, adjusted, and tightened based on the object and application at hand. This is what separates our BESSEY clamp ranges into different categories of applications, such as a Bar Clamp, a Spring Clamp, a Heavy-duty Clamp, a Sash Clamp, or a Corner Clamp – all of which are suited to particular applications.

BESSEY has a large range of specialised clamps, these clamps are designed for a bunch of different applications in woodworking and metalworking. Wood clamps are there to help you with every task in a woodworking workshop, from using an F clamp for gluing wood, to holding down plywood while you cut it with a jigsaw. Metalworking clamps are here to make your life easier, like when you use a G Clamp for welding or working with fixing bulky metal frames.

My choice as the BESSEY product specialist for building work is our BESSEY quick-grip clamps for their fast clamping action and the ability to spread as well as pull on an application. For woodworking, I recommend the BESSEY Sash Clamps for their large clamping range and ability to hold tight without slipping.

Tips For Clamping:

It may not always feel like it, but clamping is an essential Workshop application for anyone who wants to deliver quality work. Much like planning or measuring, your clamping process forms the foundation of the finished work that’s to come.

That’s why we’ve put together a small list of things you can do to increase your clamping accuracy and effectiveness:

ALWAYS WORK ON A FLAT SURFACE:

Working on a buckled or warped surface can throw your clamp, which could result in twisting and inaccurate work. If you have no choice but to work on an unequal surface, some of our BESSEY clamps have adjustments so that clamping can be done on an unequal surface.

Nevertheless, it is good practice to ensure that all of your work in a workshop is performed on a flat surface to ensure the best end results.

PLACE YOUR CLAMPS IN OVER & UNDER POSITIONS:

This is to prevent your work from twisting, as it spreads the clamping force evenly over the object being clamped. This is especially important when gluing large laminate boards together. To help you ensure your work never warps or twists BESSEY has a wide variety of clamps from light-duty to heavy-duty performance clamps. It all depends on the project you are working on right now.

SELECT THE CORRECT JAW SIZE:

This is an important part of choosing the right clamp. Jaw size refers to the distance between the two points of contact with the application; the larger the clamp, the larger the jaw size and application range. Jaws that are undersized will damage the workpiece and an oversized jaw may not provide enough concentrated clamping power where it is needed.

SELECT THE CORRECT THROAT DEPTH:

Just as with the clamp jaw size, the clamp throat depth also plays an important role in choosing the correct clamp for a given application. The throat depth refers to the distance the jaws have to reach over the work distance. The wider the material being clamped the greater the throat depth so that the pressure is distributed evenly across the work surface.

USE CLAMPS WITH HIGH RATED PRESSURE:

This is an important part of choosing the right clamp. Jaw size refers to the distance between the two points of contact with the application; the larger the clamp, the larger the jaw size and application range. Jaws that are undersized will damage the workpiece and an oversized jaw may not provide enough concentrated clamping power where it is needed.

Stop Clamping Around & Invest In The High-Quality Extra Hands Your Workshop Needs

Your workshop deserves the best because the quality of work you create is held to a high standard by yourself and your customers. BESSEY has a wide range of clamps that no other brand can hope to match when it comes to quality and the ability to assist in niche applications. We want to help your projects excel and believe that it all starts with the ability to set a good foundation around the work you do. BESSEY has a clamping solution that will save you time, make your life easier, and allow you to create high-quality work. All you need to do is discover it.