fischer Frame Fixing SXRL: An Engineering Perspective on Secure Structural Fastening

In the world of structural engineering and architectural design, the importance of secure fastening cannot be overstated. The choice of anchors, such as the fischer Frame Fixing SXRL, plays a pivotal role in ensuring the stability, longevity, and safety of structures. From an engineer’s perspective, this article will delve into the technical intricacies of the fischer Frame Fixing SXRL, its product range, key values, and the critical implications of selecting the correct anchors in structural engineering and architectural design.

Understanding fischer Frame Fixing SXRL Anchors

Construction and Material

The fischer Frame Fixing SXRL anchors exemplify the fusion of robust engineering principles and high-quality materials. These anchors are meticulously crafted from premium materials to guarantee their structural integrity. The primary components include a steel expansion screw and a nylon sleeve.

- Steel Expansion Screw: Its primary function lies in facilitating secure fastening by uniformly expanding the nylon sleeve within the drilled hole. This expansion mechanism is instrumental in ensuring a dependable grip on the substrate, making it suitable for high-load-bearing applications. The advantages of the steel expansion screw are twofold: its corrosion-resistant zinc or steel plating enhances its longevity, crucial in environments exposed to moisture and harsh conditions, and its steadfast expansion mechanism provides a reliable and stable anchor point, safeguarding structural integrity in diverse engineering and construction scenarios.

- Nylon Sleeve: The nylon sleeve is equally vital, serving as a load distribution element, spreading the load evenly across the substrate. Nylon does not deteriorate with age, ensuring long-term reliability. When subjected to heat, nylon remains stable, contrasting with the deformation tendencies of plastic. Furthermore, nylon plugs retain their shape, even under substantial loads and stresses. Its superior insulating properties render it ideal for electrical applications. In the face of chemical exposure, nylon exhibits a higher resistance, adding to its durability. Additionally, nylon anchors exert higher expansion forces, providing enhanced fastening strength. Altogether, fischer nylon’s durability, stability, and resilience make it a superior choice compared to traditional plastics in a wide array of engineering and construction applications.

Product Range and Variability

fischer Frame Fixing SXRL anchors are available in a diverse range of sizes, making them adaptable for various applications and load requirements. Engineers and architects can select from this range to match the specific demands of their projects, ensuring a perfect fit in terms of anchor diameter and length.

This variability is essential in catering to the dynamic needs of structural engineering and architectural design. Whether you’re fastening structural elements, facades, cladding, or even handrails, having the right anchor size is crucial to maintaining the structural integrity and safety of the project.

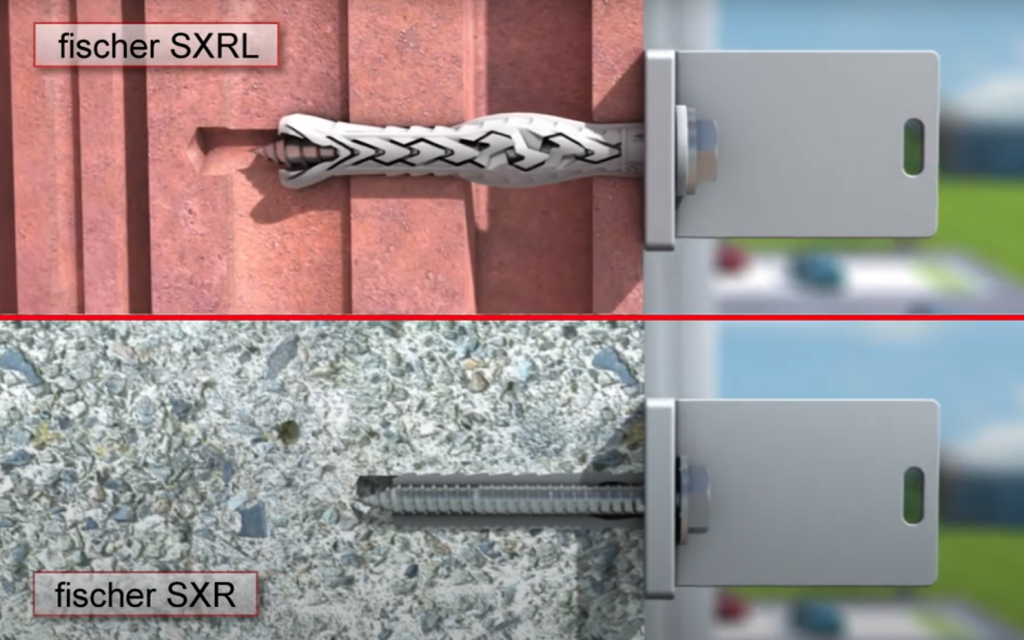

Figure 2: Product range of the Frame fixing SXRL with countersunk head screw, Frame fixing with hexagon head screw, and Frame Fixing SXRL without safety screw respectively[1]

Key Values and Engineering Principles

1. Load-Bearing Capacity

The SXRL anchors are engineered to provide high load-bearing capacity. This is crucial for structural elements that need to bear substantial loads, such as beams, facades, or heavy fixtures. The careful design of the steel expansion clip ensures that the load is distributed evenly, reducing the risk of shear or pullout failures.

2. Corrosion Resistance

Corrosion can be a silent but destructive force, particularly in outdoor or humid environments. The zinc-plated steel expansion screw and non-corrosive nylon sleeve make the SXRL anchors resistant to corrosion. This resilience ensures the long-term durability of the fastening, contributing to the overall structural integrity.

3. Ease of Installation

Engineers appreciate the ease of installation offered by the SXRL anchors. The simplicity of the process means less room for error and faster project completion, a crucial aspect of meeting deadlines and budget constraints.

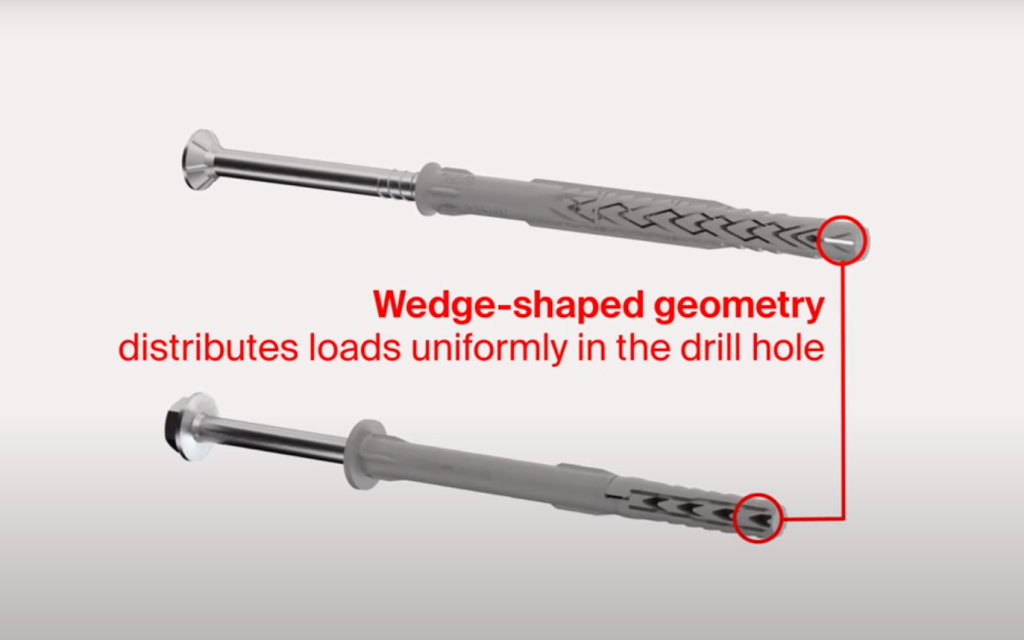

Figure 3: The Frame Fixing SXRL installation process and demonstration of the wedge-shaped geometry of the SXRL[1]

Applications of fischer Frame Fixing SXRL Anchors

fischer Frame Fixing SXRL anchors find wide-ranging applications across the field of construction and engineering due to their versatility and reliability. These anchors are engineered to secure heavy fixtures and structures in various substrates. Here are some key applications:

1. Securing Window and Door Frames

One of the fundamental applications of SXRL anchors is securing window and door frames to concrete or masonry walls. The robust steel expansion screw and nylon sleeve combination provide a strong and stable anchor point, ensuring the frames remain firmly in place over the years.

2. Fastening Handrails and Railings

In both commercial and residential settings, SXRL anchors are employed to fasten handrails and railings securely to walls. This is crucial for providing safety and stability, particularly in high-traffic areas or elevated platforms.

3. Facade Panel Installation

For the installation of exterior wall cladding and facade panels, SXRL anchors play a crucial role. Their ability to withstand varying weather conditions while providing a reliable grip makes them ideal for ensuring the facade panels remain firmly attached to the structure.

4. Hanging Heavy Fixtures

SXRL anchors are genius at supporting heavy fixtures such as cabinets, shelves, or artwork on walls. This application demonstrates the anchor’s high load-bearing capacity and stability, critical for maintaining the integrity of the fixtures and ensuring user safety.

5. Mounting Electrical and Plumbing Fixtures

During electrical and plumbing installations, SXRL anchors prove invaluable. They are utilized to securely mount electrical panels, conduit clips, plumbing fixtures, and other essential components to walls, guaranteeing their stability and functionality.

6. Installing HVAC Systems

For securely installing heating, ventilation, and air conditioning (HVAC) systems, SXRL anchors play a vital role. These anchors provide a reliable fastening solution for mounting various components of the HVAC system, ensuring proper and safe functioning.

7. Anchoring Structural Components

In larger construction projects, SXRL anchors are employed to anchor structural components such as beams or columns to the building’s framework. This application underscores the anchor’s load-bearing capacity and its critical role in maintaining the overall structural integrity.

8. Fixing Shelving Units

SXRL anchors are a go-to choice for fixing shelving units securely to walls. Whether in residential spaces, offices, or retail stores, the anchors ensure that the shelving remains stable and can support the intended load without risk of detachment.

In summary, fischer Frame Fixing SXRL anchors find extensive use in anchoring a variety of fixtures, structural components, and panels. Their versatility, durability, and high load-bearing capacity make them indispensable in the realm of construction, ensuring the safety, stability, and longevity of the anchored elements. Engineers and builders rely on these anchors to execute a wide array of projects with precision and confidence.

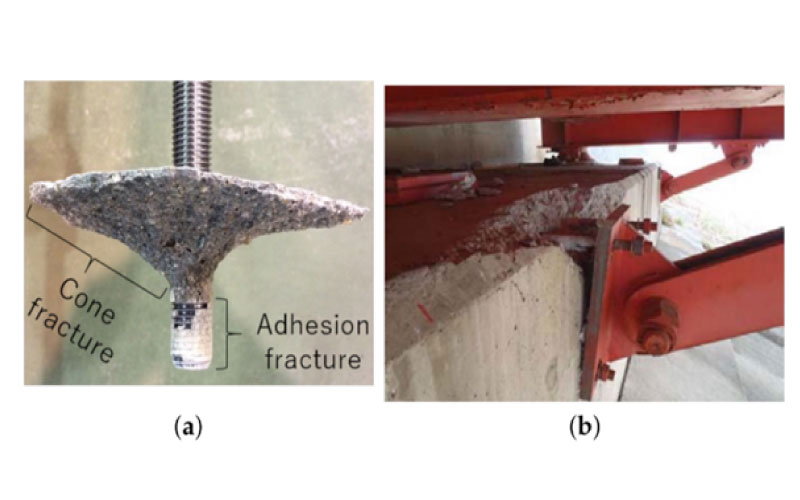

Importance of Correct Anchor Selection

Selecting the correct anchor is not a trivial task in engineering and architectural design. A mismatch between the anchor and the load or the substrate can have dire consequences.

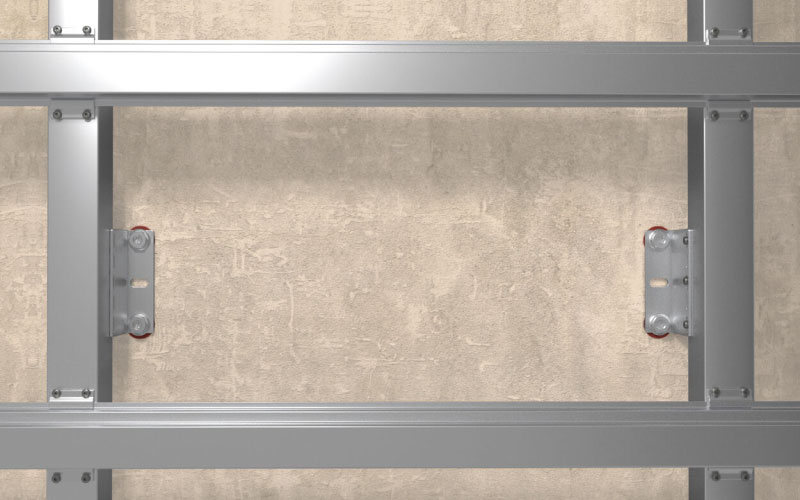

Figure 4: Typical examples of structural failures due to incorrect anchor selections[1]

Structural Integrity

An incorrect anchor can jeopardize the structural integrity of a building. Overloading or underloading an anchor can lead to failures, causing safety hazards and requiring costly remediation.

Aesthetic Considerations

In architectural design, anchors can also impact the aesthetics of a structure. Using oversized anchors may affect the visual appeal of a facade or cladding. Conversely, using anchors with insufficient load capacity might compromise the design by restricting the choice of materials or configurations.

Budget and Project Timelines

Incorrect anchors can lead to project delays and budget overruns. Repeated anchor failures or revisions to the fastening system can be expensive and time-consuming.

In Retrospect

fischer Frame Fixing SXRL anchors are a go-to solution for engineers and architects who understand the vital role of secure fastening in structural integrity and architectural design. With their high load-bearing capacity, corrosion resistance, and ease of installation, they embody the values and principles crucial in the field of engineering. Correct anchor selection is not only technical but also an economic and safety-driven decision. The repercussions of an incorrect choice can be far-reaching, impacting everything from structural stability to project budgets. Engineers and architects who prioritize the selection of the right anchors, such as the fischer Frame Fixing SXRL, contribute to safer, more durable, and visually appealing structures.

The Way Forward

For engineers in South Africa, the fischer technical team at UPAT SA provides valuable support. Our services encompass training, webinars, and seminars, which equip professionals with the knowledge and skills needed to make informed anchor selections at no cost.

Additionally, we offer training in using the free Fixperience software, which is a vital tool in the selection and calculation of suitable fischer anchoring products for specific applications. It’s a valuable tool for engineers, architects, and construction professionals to ensure that the chosen anchors meet the technical requirements and safety standards of a given project.

fischer Frame Fixing SXRL anchors, coupled with the expertise of the UPAT SA technical team, represents a synergy of innovative engineering solutions and technical support, ensuring the reliability and durability of construction projects across South Africa and beyond.