Unseen Precision: Understanding Tape Measure Accuracy

When it comes to measuring, the most accurate tape measure is the one in your hand. But what makes a tape measure truly accurate? It’s not just about the user’s skill; it’s about the tape’s construction, markings, end hook, and more. In this exploration of tape measure accuracy, we delve into the crucial factors that influence precision.

1. Tape Markings:

The clarity and precision of markings on a tape are vital. They must be easily visible to minimize errors. Whether in metric or imperial units, the lines should be thin yet distinct. A thick line can lead to confusion about the exact measurement point. The coating over the markings should be clear, non-distorting, and durable enough to withstand wear and tear ensuring markings do not fade away or scratch over time when in use. Extremely hard-wearing coating protects the tape against abrasion and corrosion.

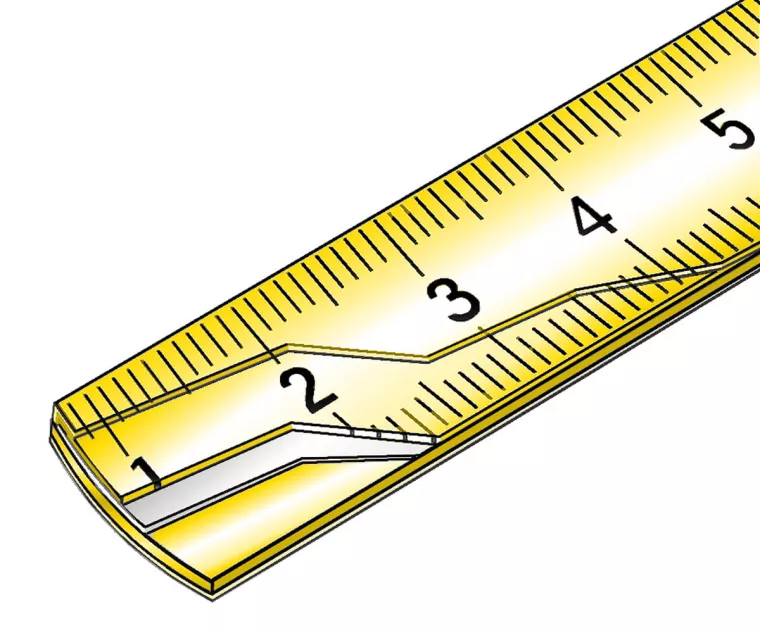

Different Types of Blades

The material of the blade of STABILA tape measures differs depending on the design and model. A distinction is made between steel and fiberglass tape measures that, dependent on the area of application, offer tradespeople the perfect solution for every measuring task.

STABILA measuring blades have a yellow coating ensuring they are easy to read even in sunlight. Different applications and working environments require different measuring blades to ensure ultimate accuracy and durability. Let’s have a look at the different types of blades and unpack when one version is preferred over another.

Steel Blade

Tape measures with steel blades provide accurate measurement results. The measuring scale is protected by paint or a coating.

With its extremely hard-wearing STABILA NYLON-WRAP blade coating that prevents the blade from corroding and the measuring scale from being rubbed off by dirt particles, the BM 300 pocket tape is particularly sturdy for everyday construction site conditions.

EC accuracy class II applies to STABILA steel measuring blades as standard

Fibreglass Blade

The hard-wearing tape measure made of plastic reinforced with fiberglass guarantees excellent durability. Fiberglass blades are impervious to moisture and are easy to use due to their low weight. Damage caused by bending the tape is prevented by STABILA KINK PROTECTION. EC accuracy class III applies to STABILA fiberglass tape measures as standard.

2. Tape Thickness:

The thickness of the tape material is essential for accuracy. It must be thick enough not to stretch or tear, especially when extended over long distances. Users who push the tape to its limits risk stretching it, potentially compromising measurements. Durability in various working conditions is crucial.

Thick and curved steel blades ensure a high level of stability and rigidity of the tape measure and can be pulled out by up to 3m without kinks.

Hard-wearing fiberglass tape prevents damage of the tape caused by bending the tape.

3. End Hook Grip and Precision:

The end hook’s grip is critical to prevent slipping, even at slight angles. The movement of the end hook should correspond precisely to its thickness to ensure accuracy for both inside and outside measurements. Over time, the hook should not become loose at the rivet points or wear out to ensure consistent accuracy is maintained.

4. Tape Marking Accuracy:

The European Commission has established a system for certifying tape measure accuracy, with certified tapes falling into one of three classes: Class I, II, and III. These classes have specific tolerances for accuracy over a 10m length:

- Class I: Accurate to ±1.10mm over 10m.

- Class II: Accurate to ±2.30mm over 10m.

- Class III: Accurate to ±4.60mm over 10m.

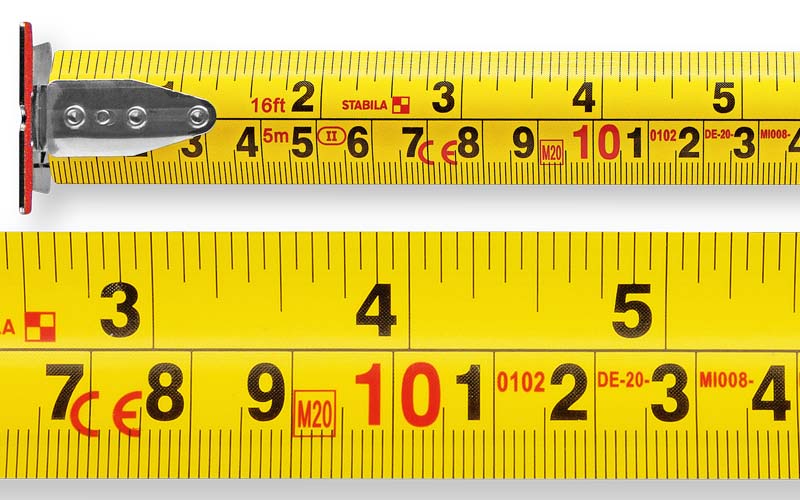

The class rating is printed on the tape, along with manufacturing details, for certified tapes.

High-quality tape measures are recognised by the different markings at the start of the tape:

(1) Nominal length

(2) EC accuracy class

(3) Manufacturer’s brand

(4) CE marking

(5) Metrology marking and year of manufacture

(6) Registration number and EC Type Examination Certificate

Why Tape Measure Accuracy Matters:

Imagine you’re working on a project, and you measure a kitchen marble countertop that’s supposed to be 20 meters long. However, your tape, from Company X, is a Class III, which means it could be off by up to 4.6mm per 10 meters, making it 9.2mm too long.

At the factory, the artisan cutting the marble slab uses a tape from Company Y, that has Class III classification, meaning it is out by 6.6mm per 10 meters, making it 9.2mm too short. When you install the countertop on-site, it doesn’t fit correctly because of the discrepancy in tape accuracy.

The solution is simple: ensure that all tapes used on-site and in the factory are the same brand, model, and batch. Verify their accuracy against each other. This eliminates the variability in measurements. Combine this with proper staff training and purchasing from reputable brands to ensure consistent and accurate measurements every time and avoid having to do the job twice. In conclusion, the precision of a tape measure goes beyond the tape itself; it’s about understanding its construction, markings, and class accuracy to achieve dependable results in your projects.