Why Approvals And Certifications Matter

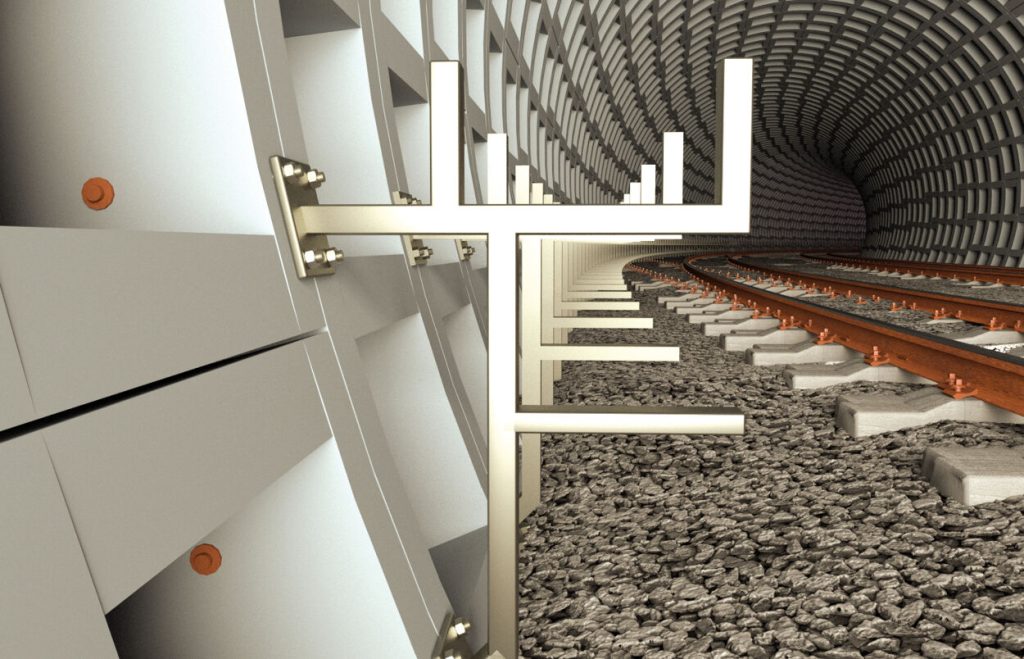

Ever wondered why some products have embossed markings engraved, or laser printed onto them, and what these markings signify? This refers to the quality mark of a product and is generally associated with a governing body that issues product approvals and assessments following stringent testing of products in various conditions and under various pressures and environments. Approvals and certifications are technical documents that stipulate technical information pertinent to different products available in the market. It is extremely important to know which products you’re using need and have approvals, as well as the type of approval associated with them. Since the fixings industry is centered around safety, it is imperative to recognise technical approval markings and know what they mean.

In this article, we discuss the various types of approvals and certifications associated with fischer products so you are better informed on which type of fixing to choose for your given application. Each product has a variety of different approvals, showcasing the quality and performance of each fischer product.

1. European Technical Approval/Assessment :

The European Organisation for Technical Assessments (EOTA) is the body that issues Technical Assessments (ETA) within the European Union. They are similar to the South African bureau of Standards (SABS) except that the assessments cover multiple European Member countries. If a product has an ETA assessment, it also allows the manufacturer to place a CE mark (Attestation of Conformity) on the product.

There are 12 options for ETA Assessments. Options 1 – 6 are for cracked concrete, with Option 1 being the highest level for this category. Options 7 – 12 are for non-cracked concrete, with Option 7 being the highest level for this category.

All of fischer’s anchors have an ETA assessment with either Option 1 or Option 7 and have passed the most stringent of the prescribed tests. It is vitally important to note which EOTA option a manufacturer has used when testing their anchors, as Option 2 is not as intensive as Option 1 and Option 8 is not as intensive as Option 7.

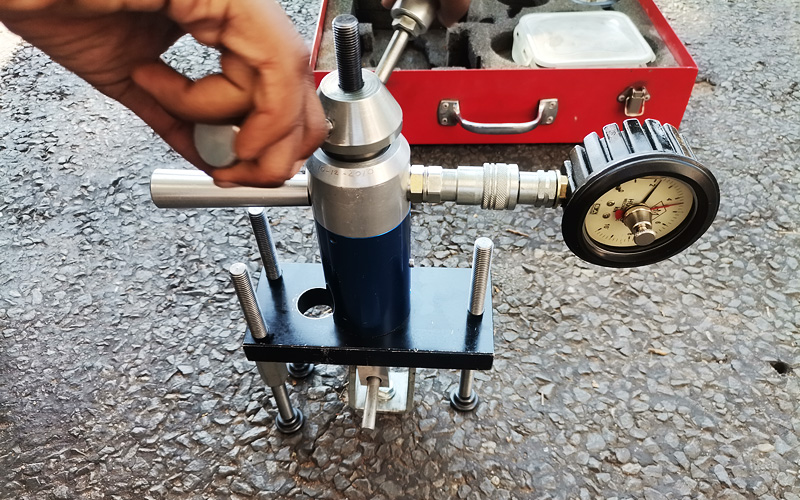

1. ETA Testing

For an anchor to have an ETA Assessment associated with it certain tests are performed on a batch of samples whereby anchors are put through rigorous tests that replicate job site conditions and if they are found to perform to the required level they receive an allocated ETA Assessment. With Options 1 and 7 the testing is outlined in ETAG 001 (2013).

The anchor must fulfill these requirements:

- The anchor’s predicted lifespan is at least 50 years.

- The anchor should work in a temperature range of -40°C to +80°C.

- The anchor should behave in a predictable manner.

- The displacement of the anchor shall remain within preset limits.

- Anchors should not fail by breakage or cause the concrete to fail during the installation process.

- The anchor’s characteristics should not change during the lifetime of the anchor.

A brief list of the tests required for Option 1 is as follows:

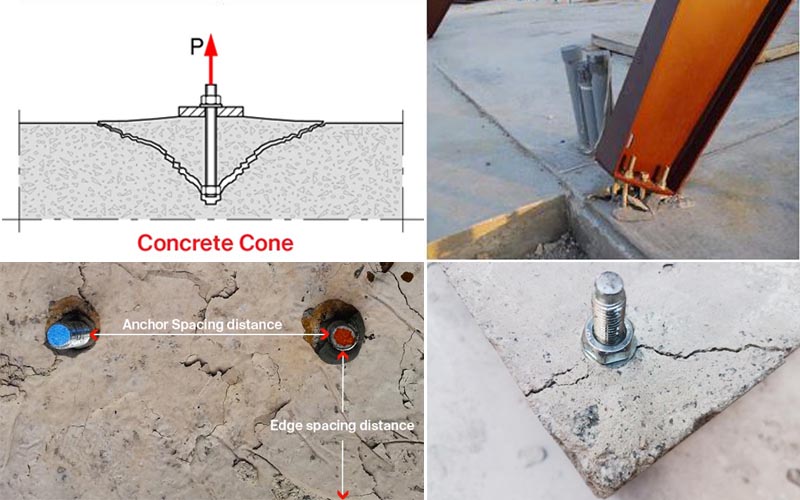

- Tensile test with no edge or spacing influences. (4 tests – 2 different concrete strengths, with and without a 0.3mm crack)

- Shear test with no edge or spacing influences. (4 tests – 2 different concrete strengths, with and without a 0.3mm crack)

- Combined tension and shear with no edge or spacing influences. (4 tests – 2 different concrete strengths, with and without a 0.3mm crack)

- Spacing for characteristic tension resistance.

- Edge spacing for characteristic tension resistance.

- Shear resistance in non-cracked concrete for pry-out failure.

- Shear resistance in non-cracked concrete close to an edge. (2 tests for different concrete strengths)

- Shear resistance in cracked concrete close to an edge.

- Spacing and edge distance for characteristic shear resistance.

- Minimum edge distance and spacing.

Anchors with the Option 7 ETA must meet the same test results but the 0.3mm crack removed. In addition to the tests above the following criteria will be assessed:

- Crack movement tests.

- Repeated load tests.

- Sustained load test.

- Torque tests.

Partial safety factors are also evaluated from the results of the installation safety tests. This safety factor covers the following installation issues:

- Cleaning of holes.

- Moisture content in the concrete.

- Undercutting in the case of undercut anchors.

- Installation torque.

- Expansion of deformation-controlled and undercut anchors.

- Mixing of mortar in the case of bonded anchors.

- Striking of reinforcement.

The fabrication method (e.g. cold forming, machining, quenching, hardening) shall also be tested. The factory quality control is also taken into account, especially with the allocation of the Attestation of Conformity (CE mark).

2. ICC = International Code Council, formed from BOCA, ICBO & SBCCI

ICC Evaluation Service Inc. (ICC ES) issues reports, e.g. for subsequent anchoring on the basis of the International Building Code® and the related standards in the United States of America. This approval can be found on a variety of heavy-duty steel and chemical anchors.

Common products with this approval: Bolt Anchor FAZ II, High-performance anchor FH II, FIS V Plus, FIS EM Plus, Superbond system FSB

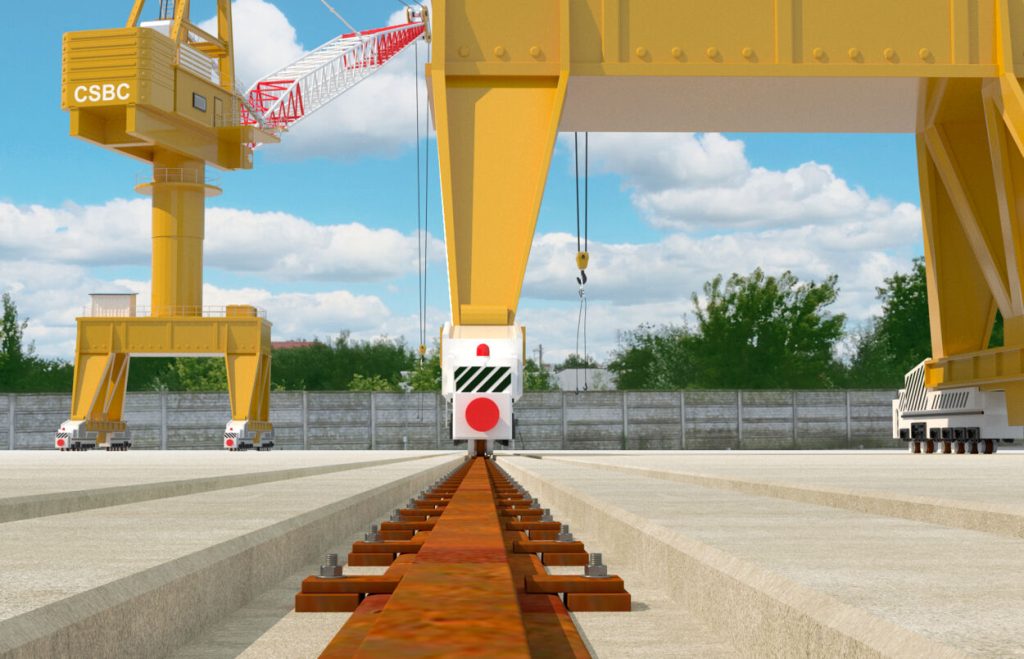

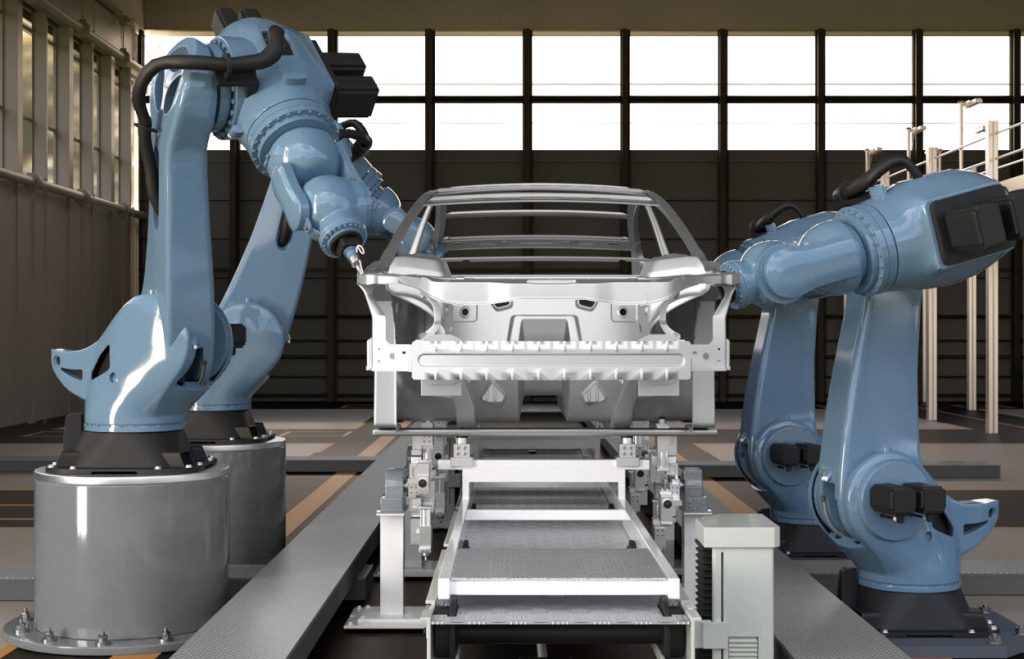

FAZ II Anchor Applications

FH II Anchor Applications

FIS V Plus Chemical Mortar & Anchor Applications

3. FM Certificate

Recognized for use in local water-based fire extinguisher systems (Factory Mutual Research Corporation for Property Conservation, American insurance company). Common products with this approval: Bolt Anchor FAZ II, High-performance anchor FH II, Zykon Undercut anchor FZA.

Zykon Undercut anchor FZA

4. General Building Authority Approval

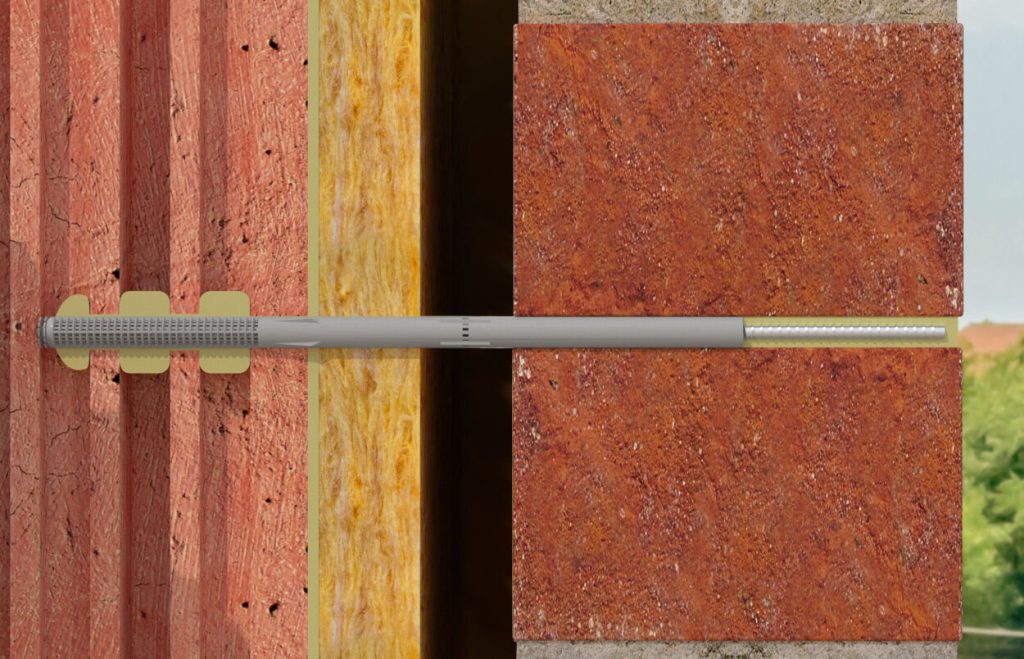

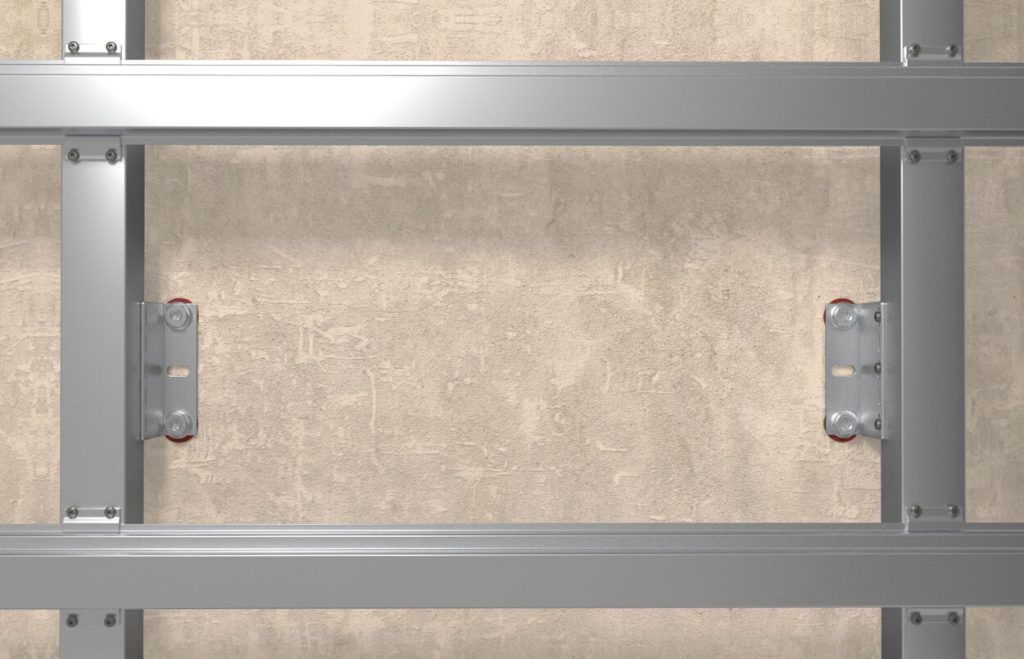

German approval, issued by the DIBt, Berlin with the accompanying certificate of conformity for construction products with the general building authority approval. Confirmed by a material testing institute. Common products with this approval: Remedial wall tie VBS 8.

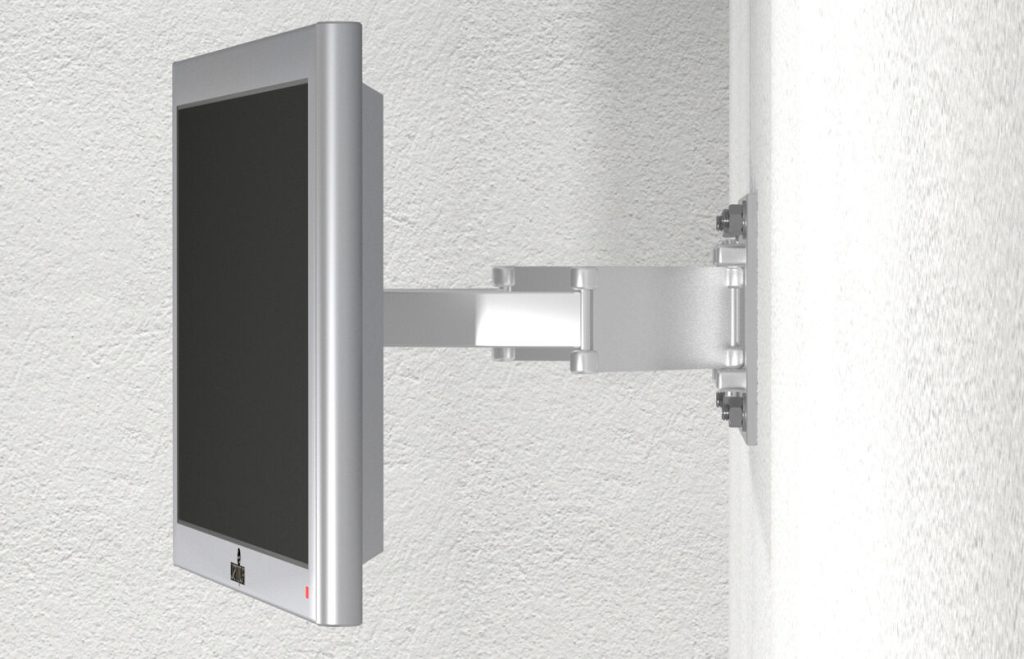

VBS Remedial Wall Tie

5. Fire-tested fixing

German approval, issued by the DIBt, Berlin with the accompanying certificate of conformity for construction products with the general building authority approval. Confirmed by a material testing institute. Common products with this approval: Bolt Anchor FAZ II, High-performance anchor FH II, Superbond system FSB, Resin Anchor RM II, FIS EM Plus, Zykon Undercut anchor FZA, Concrete screw Ultracut FBS II.

FIS SB Super Bond Chemical Mortar

RM II Resin Capsule

FIS EM Plus Chemical Mortar

FBS II Ultracut Concrete Screw

6. INOX Stainless steel

The product is available in highly corrosion-resistant steel of corrosion resistance class IV, e.g. 1.4529. Common products with this approval: Bolt Anchor FAZ II, High-performance anchor FH II, Superbond system FSB, Zykon Undercut anchor FZA.

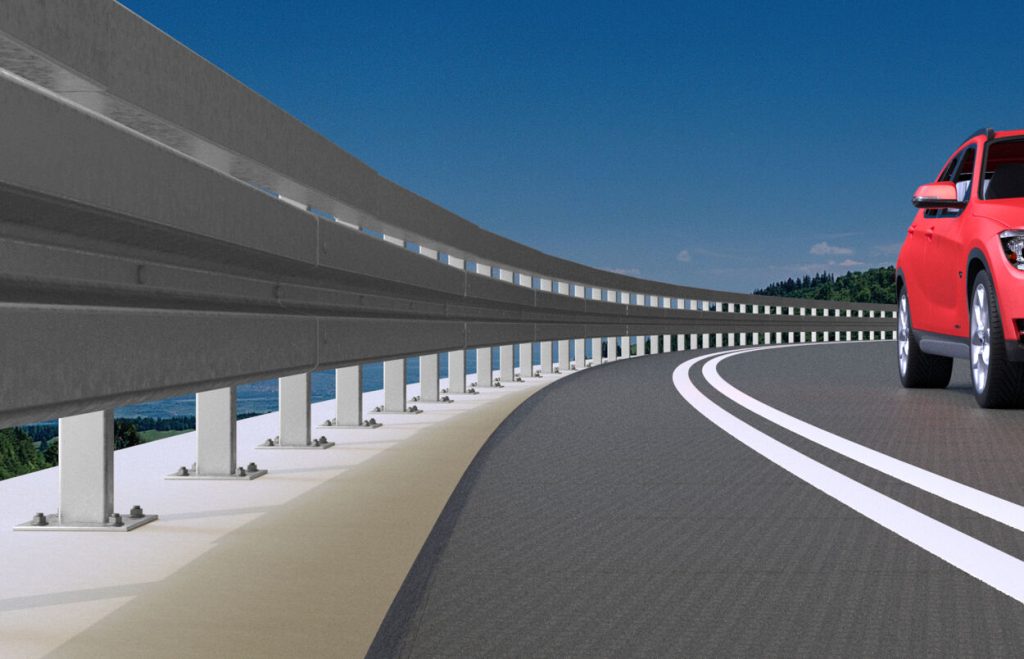

7. Dynamically loadable anchors

The anchor is suitable and approved for anchoring “not predominantly static” (i.e. dynamic) loads. static” (i.e. dynamic) loads. static” (i.e. dynamic) loads. Common products with this approval: Superbond system FSB, Highbond System FHB.

FHB Highbond Chemical Mortar

8. Seismic Approval

The fixing is suitable for anchoring under seismic influence. Please note: The ICC-ESRs also allow seismic stress (see Category C1 and C2 in accordance with the ETAG 001 Annex E). Common products with this approval: Bolt Anchor FAZ II, High-performance anchor FH II, FZA, FIS EM Plus, Superbond System FSB, Concrete screw Ultracut FBS II.

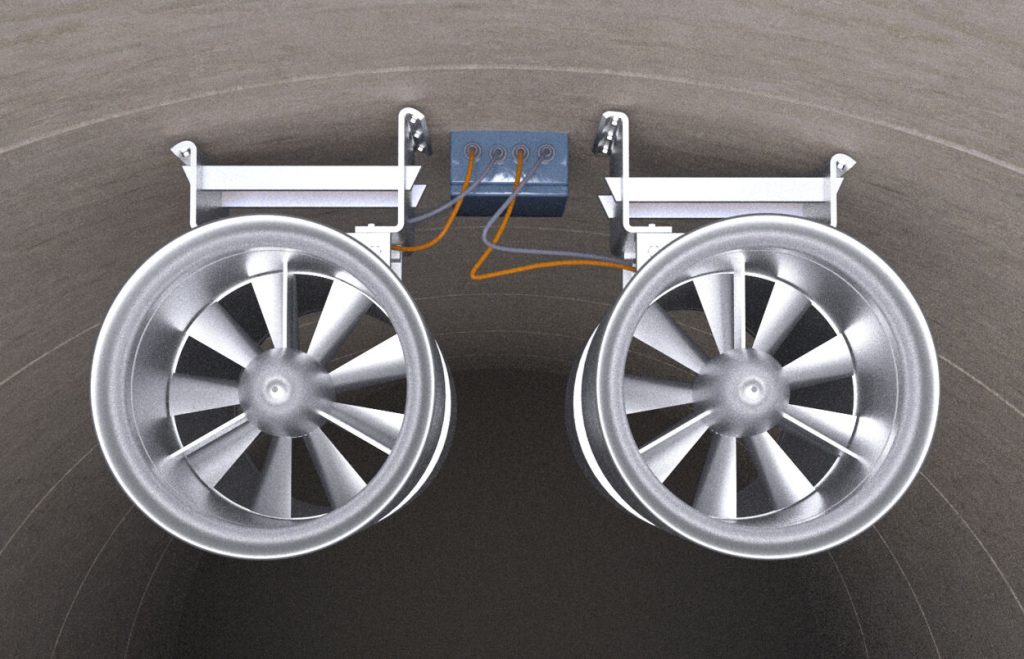

9. Sprinkler systems

Mark for labels that confirm compliance with the VDS-CEA guidelines for sprinkler systems, planning, and installation. Fixings labeled as such may be used for fixing pipes for extinguishing systems. Common products with this approval: Bolt Anchor FAZ II, High-performance anchor FH II, FZA, Concrete screw Ultracut FBS II.

10. Nylon approval

Fixing is made of high-quality, aging-resistant nylon (polyamide). Common products with this approval: Frame fixing SXRL, Universal Plug UX, Duopower Universal Plug, Expansion Plug SX.

SXRL Frame Fixing with countersunk head screw

SXRL Frame Fixing with hexagonal head screw

UX Universal Plug

Duopower Universal Plug

SX Expansion Plug

11. Window frame fixing

Component test with window frame screws in accordance with guideline M0-01/1; Testing structural connections on windows. Common products with this approval: Window frame screws FFSZ and FFS.

FFSZ Window Frame Fixing

FFS Window Frame Fixing

Conclusion

The fourteen different levels of approval certification show the product’s credibility to perform in the stipulated conditions. Each fischer product has different approvals to ensure quality is achieved in the final fixing application providing installers with ease of mind knowing that if it’s been fischer fixed it’s not budging.