Mechanical Steel Anchor Bolts

Anchor connections are generally used in steel-to-concrete connections to transmit loads from one element to another via anchor bolts. The anchor bolts are used to distribute load actions into their base material and are influenced by key parameters such as its base material, load bearing capacities, and anchor failures of the most unfavorable anchor.

High-Performance Steel Anchor Bolts

Mechanical steel anchors work on the principle of expansion or undercut theory. This principle uses mechanical interlocking and friction to hold an anchor into its base material. The mechanical interlocking of anchors transfers the load to the base material by locking against the base material. Expansion anchors work on the principle of friction to create a force between the anchor and its substrate. In this section, we look at different types of mechanical steel anchors and study the approvals associated with each anchor.

The performance of any steel anchor relies on the steel’s material properties, as well as, the engineered design for its anchor properties. Steel anchors are available in carbon steel, stainless steel, and hot-dipped galvanized steel, which explains the different forms of corrosion protection. Another influencing factor that affects performance is to consider the location of fixing – since the overall weather conditions will affect the lifespan of an anchor connection. For example, it is highly recommended that stainless steel anchors be used in coastal regions since it is classified as a highly corrosive environment.

Product Technical Review on Popular Mechanical Anchors

3.1. fischer Express Anchor Bolts

Express anchors are for push-through and pre-positioned installations. This type of anchor is typically used in uncracked concrete and is suitable for fixing steel constructions. The Express anchor is available in different sizes with variations in corrosion resistance and steel properties. The powerful expansion provided by this mechanical bolt anchor ensures that there is minimal slippage when tightening.

Anchor Applications

- Steel constructions

- Guard rails

- Consoles

- Ladders

- Cable trays

- Machines

- Staircases

- Gates

- Façades

Approved Building Materials

Approved for:

- Concrete C20/25 to C50/60, non-cracked

Also suitable for:

- Concrete C12/15

- Natural stone with a dense structure

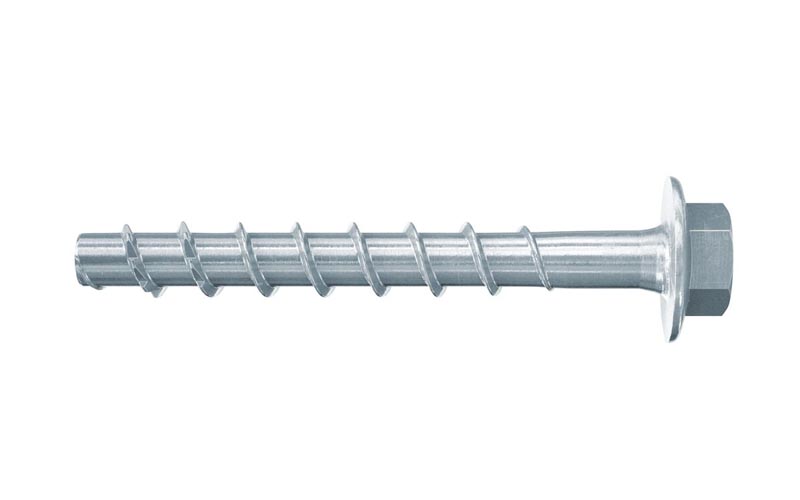

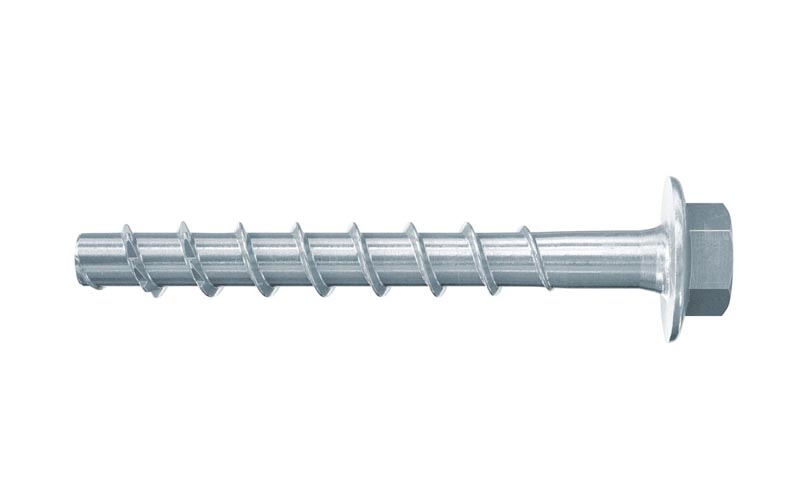

3.2. fischer FBS Concrete Ultra Cut Screw

The Ultracut concrete screw is the next type of steel anchor that will be unpacked. This type of screw is available in various lengths and offers a flexible adaptation of the embedment depth to the loads. This screw is approved for use in cracked and uncracked concrete and has the highest safety requirements in terms of European Technical Approvals.

One specific function of this screw is its ability to be used in temporary structures – the unique design allows for this screw to be reused without compromising the integrity of its capabilities.

Anchor Applications

- Guard rails

- Consoles/Base plates

- Metal profiles

- Shelving systems

- Protection barriers

- Results/ beam anchors

- Temporary anchoring, e.g. of building site equipment

- Shuttering props

- Reinforcement of bridges

- Rehabilitation of old and ailing buildings

- Rehabilitation of car parks

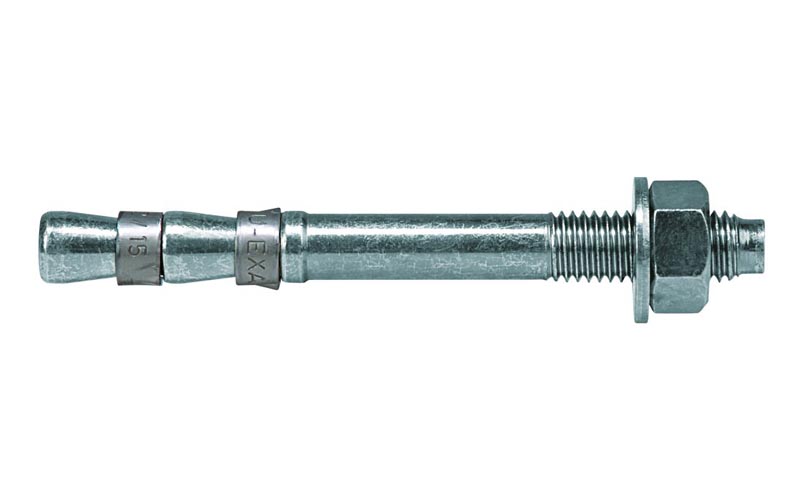

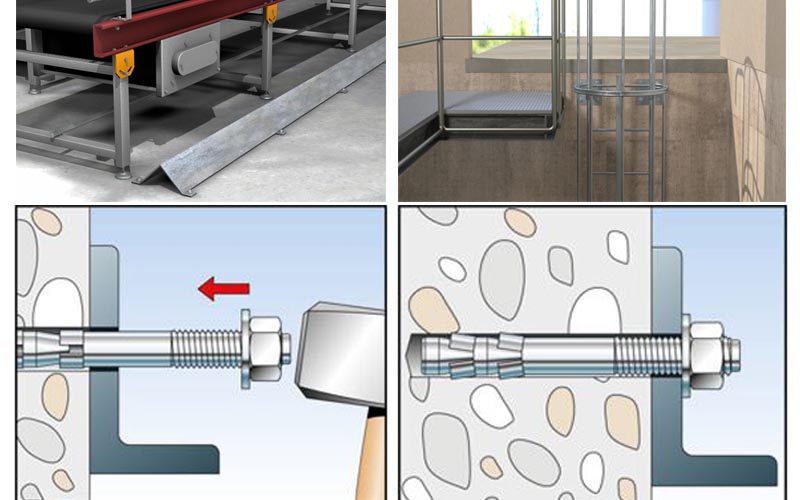

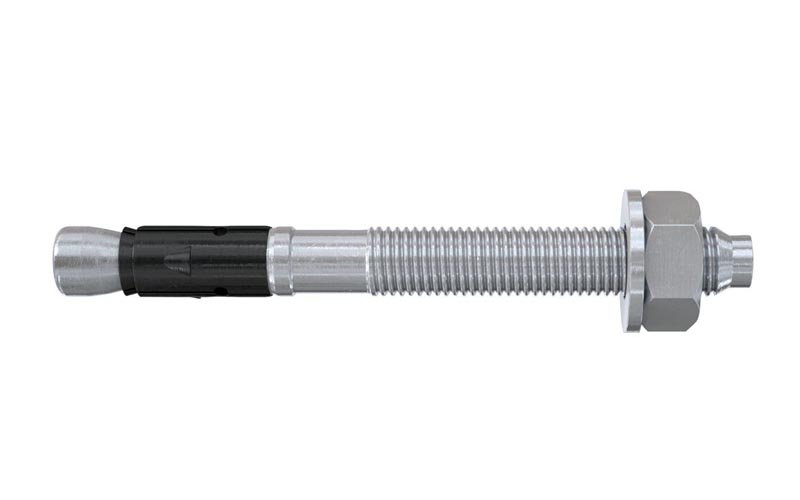

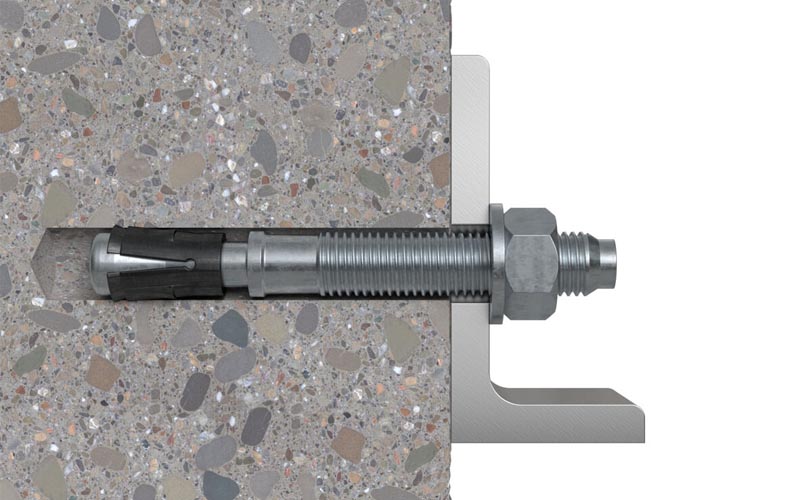

3.3. fischer FAZ II Bolt Anchor

This type of anchor bolt is most commonly used in steel construction. fischer has now improved the design of FAZ Anchor Bolt which allows for high tensile load capacities which are approved for use in cracked and uncracked concrete.

The FAZ II Anchor Bolt requires a pre-set torque when setting this anchor. When applying the torque the cone bolt is pulled into the expansion sleeve and expands it against the drill hole wall.

Anchor Applications

- Steel constructions

- Guard rails

- Consoles

- Ladders

- Cable trays

- Machines

- Staircases

- Gates

- Façades

- Timber constructions

Case Study

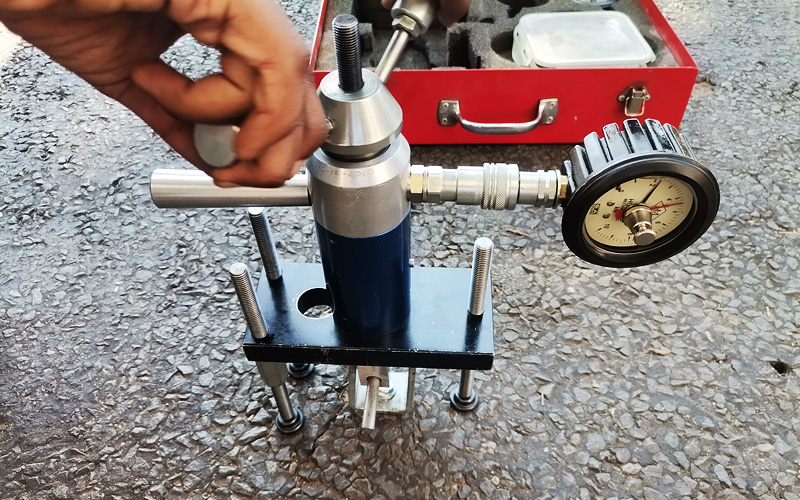

Mechanical steel anchors are used in a wide range of applications for different functions in the building and construction industry. The case study discussed below shows the versatility of the FBS Ultra Cut Concrete Screw and explores the installation and testing of the anchor in tar.

The purpose of this test was to determine which type of fixing would be most appropriate for use in tar. For this example, the FBS Concrete UltraCut Screw was selected and tensile loaded until failure. The test was repeated five times to ensure unbiased results and an average ultimate failure load of 4 kN (407,89 kg) was achieved. This shows that the FBS Concrete UltraCut screw is able to withstand 40 kg of tensile force.

In industry, these types of applications can be seen with fixing rubber speed humps into tar. Rubber mats are slowly replacing the traditional way of constructing speed humps with tar for easy installation. Since the FBS Concrete Ultra Cut Screw can be reused, it makes this application much easier for contractors and engineers working in the road development industry.

Conclusion

Steel anchor bolts are widely used when applicable to fixing situations. This article focuses on popular steel anchors used in the industry and gives basic product information and guidelines on how to get the best results out of them. Furthermore, the case study used in this article shows the FBS Concrete Ultra Cut screw as a versatile steel fixing in South Africa’s construction industry.

Interested in expanding your knowledge of steel anchors? The training and development team from fischer has created interesting and informative online training videos to assist with understanding different types of anchoring solutions and how to select the correct fixing for your application.