How To Anchor Into Masonry

When it comes to fixing an anchor into masonry it is typically used to infill load-bearing walls in conjunction with reinforced concrete columns or as internal partitioning. Masonry is everywhere and Jobsite professionals need to know how to go about anchoring into it to ensure a solid and secure hold that will stand the test of time.

Masonry structures contribute a large portion to the building and construction industry in South Africa. Masonry walls are made up of individual blocks (brick, clay, aerated concrete, etc.) that are laid in interlocked horizontal rows and bonded with cementitious mortar.

Why Do You Need To Anchor into Masonry:

Although masonry walls aren’t meant for heavy structural purposes such as anchoring structural steel for example, there are many applications that require fixing into masonry substructures. Such as putting up guide rails, and fixing awnings or signage. The wide variety of possible applications makes it quite technical to anchor into.

That’s why it’s essential to discuss and understand the strength capacities, brick composition, which way the brick is laid, and failure modes when working into masonry. Each one of these elements counts when it comes to finding the right fixing and ensuring the best fixing practice is followed to result in a secure installation.

Solid Brick vs Hollow Brick:

For those who do not know, solid and hollow bricks are the two most common types of brick that are used in the building industry. Why is this important? When anchoring into masonry substrate or building material, it is important to understand the composition and type of brick used.

The strength of a brick is determined by its compressive strength, a solid clay brick will have a higher compressive strength as compared to a hollow cementitious brick. Higher compressive strength means a stronger substrate for you to fix into, with the average compressive strength of concrete being approximately 30 – 35 MPa, whereas brick has a compressive strength of 5 – 7 MPa.

You always have to remember that a brick’s strength capacities are dependent on the type of brick used in a given application. Another important parameter to consider is the material composition of the brick: clay, fly ash, aerated concrete, etc. This means that each type of brick has a unique compressive strength that you need to keep in mind when looking at the various fixing applications. This is because, depending on the application and use of the masonry structure, the correct brick should be selected. Alternatively, a load test should be done to determine the suitability of a given anchor for the application.

What To Know When Anchoring Into Brickwork:

A very important element of anchoring into brickwork is the diameter of the anchor used for anchoring into the brick. Since the standard height of bricks in SA are 73mm, it is recommended that anchors in brickwork do not exceed 12mm. Assuming the anchor is placed centrally on a single brick, that leaves a limited edge distance on that brick. If larger-sized anchors are used (above 12mm), that creates limited edge distance on the brick, thus resulting in splitting failure or failure of the building material being fixed into.

Anchors Suited for Anchoring Into Brickwork:

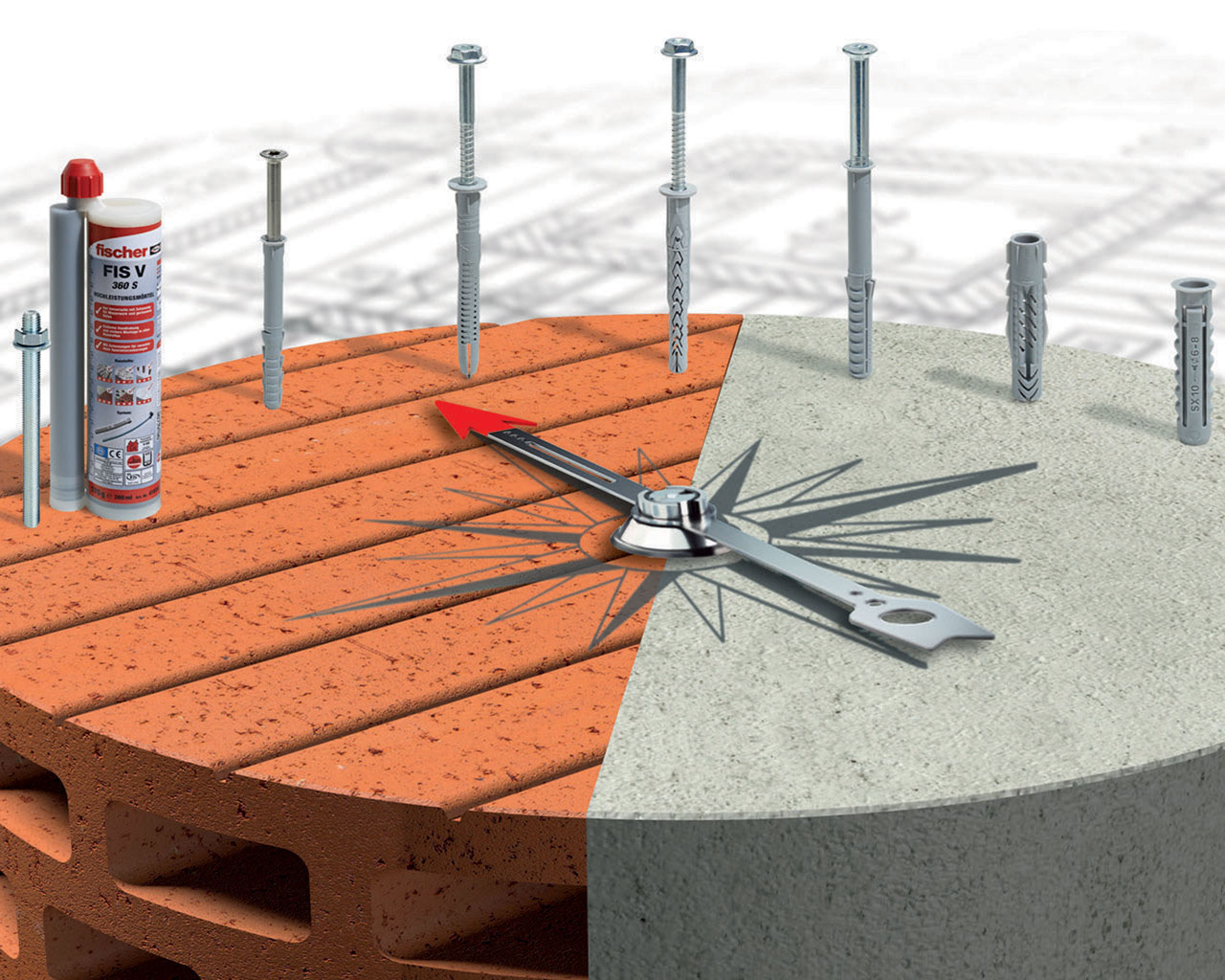

There are different anchor products available for masonry applications, let’s look at three Nylon Plugs Chemical Anchors, and Injection Anchor Sleeves.

Nylon Anchors

There are different types of nylon plugs available for brickwork installations. In hollow brick, the nylon plug is expected to expand/ mushroom in hollow sections of the brick to create an interlock between the screw, plug and brick. The SXRL, UX and Duopwer plugs are just a few examples of suitable plugs for brickwork, with the Duopower being the most effective and universal.

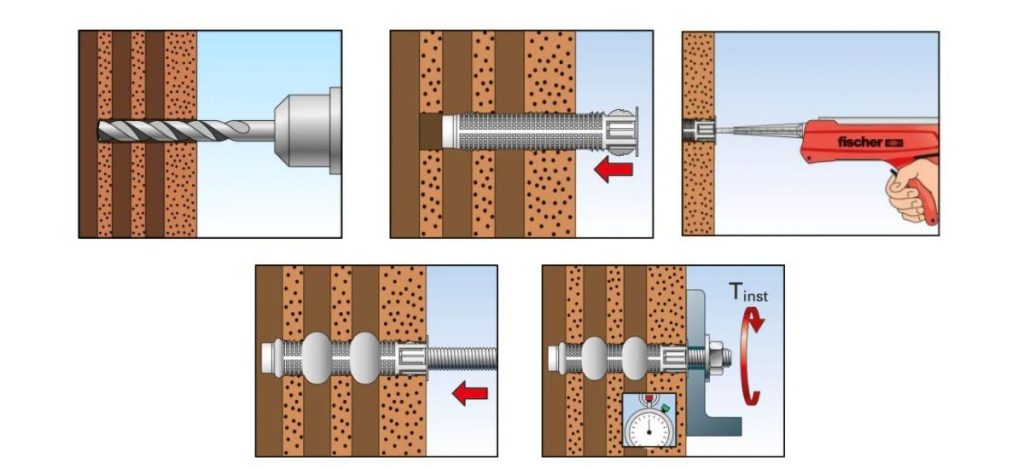

Chemical Mortars and Sleeve Anchors

Chemical anchors and injection anchor sleeves work together in hollow brick as the sleeve works as a socket that holds the chemical and stud in place. It is important to note that the sleeve should fit through the hollow section of the brick so there is maximum contact between the chemical and stud in the hollow sections. If the sleeve is inserted into the entire hole (i.e., a solid section of the brick) this limits the bond contact between the chemical, stud and brick.

Chemical anchors are most suitable for when you want to anchor into masonry, depending on the loads associated and the type of brick, either solid or perforated. A higher load when fixing into hollow bricks requires that a chemical anchor be used in conjunction with an anchor sleeve to ensure a safe and secure installation. The purpose of the sleeve is to hold the chemical in place so that it doesn’t seep into the hollow portions of the brick. This method of fixing chemical anchors into hollow brick ensures a sparing use of mortar with the best interlock fixation possible.

When it comes to setting the industry standard on anchoring and fixings fischer has you covered. We hope that you were able to get some in-depth insights into how to fix masonry with our anchoring solutions.

If you need any more information we have you covered with our fischer Inhouse Engineer who can’t wait to help you. Our team of Technical Sales Representatives and In-house Technical Manager and Engineer are here to assist with testing the substrate and are equipped with the knowledge to provide you with technical advice.